- Machine-tools

- Machining Center

- 5-axis machining center

- Kern Microtechnik GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

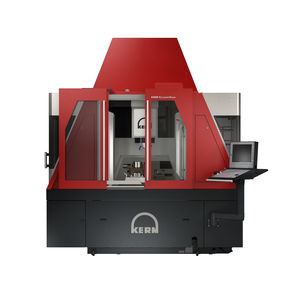

5-axis CNC machining center KERN Micro Proverticaldentalmedical

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Applications

- dental, medical, for the automobile industry, for the mold industry

- Other characteristics

- high-precision, with automatic tool changer

- X travel

350 mm

(13.78 in)- Y travel

220 mm

(8.66 in)- Z travel

250 mm

(9.84 in)- Rotational speed

30,000 rpm, 32,000 rpm, 40,000 rpm

(188,496 rad.min-1, 201,062 rad.min-1, 251,327 rad.min-1)- Power

6 kW, 6.3 kW, 7 kW

(8.16 hp, 8.57 hp, 9.52 hp)

Description

Solution for precise serial production

Since its launch on the market, the KERN Micro has stood out from the competition by combining extreme precision with unrivaled flexibility and performance. Based on a mature machine platform, the KERN Micro Pro is a solution focused on the industrial environment and precision serial production.

In many applications the focus is not on achieving a sub-2 μm precision on the workpiece, but rather on the machine’s series stability, integration capability and cost-effectiveness. The sleek KERN Micro Pro is designed to perfectly meet these requirements.

– Minimal footprint of less than 4 m2

– Uninterrupted monitoring and maintenance of lubricants during operation

– Attractive purchase conditions and maintenance costs

– High dynamics and productivity thanks to proven components and processes

– Unmanned multi-shift operation thanks to an integrated changer for up to 210 tools and up to 30 workpieces

– Certified interfaces for external units and automation systems

Due to the consistent focus on serial production, a machine was created that combines productivity, efficiency and reliability like no other. The system is based on proven, high-quality KERN technology and guarantees reliability and stability over a long machine life.

The KERN Micro is ideal for all industries requiring ultra-high precision in serial production.

– Tool/mold production

– Automotive

– Dental equipment

– Medical equipment

– Micromechanics and the watch industry

– Research and development

Related Searches

- CNC machining center

- Vertical CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- High-productivity CNC machining center

- Column type CNC machining center

- CNC machining center with pallet changer

- Precision CNC milling machine

- Compact CNC machining center

- Machining center for the automobile industry

- 5-axis CNC milling machine

- High-precision CNC milling machine

- CNC machining center with moving table

- Medical CNC machining center

- CNC milling machine with pallet changer

- CNC milling machine for the mold industry

- CNC milling center for the mold industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.