- Machine-tools

- Machining Center

- 5-axis CNC milling machine

- Kern Microtechnik GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

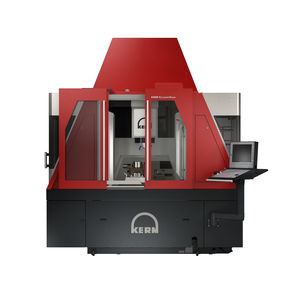

5-axis CNC milling machine KERN Evoverticalwith moving tabledental

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- with moving table

- Applications

- dental, for medical applications, for the automobile industry, for the mold industry

- Other characteristics

- high-precision, with automatic tool changer

- X travel

300 mm

(11.81 in)- Y travel

280 mm

(11.02 in)- Z travel

250 mm

(9.84 in)- Rotational speed

Min.: 0 rpm

(0 rad.min-1)Max.: 50,000 rpm

(314,159 rad.min-1)- Power

6 kW

(8.16 hp)

Description

The result of intelligent evolution!

Every KERN Evo contains many years of consistent development to ensure ultra-high precision in CNC milling at high and medium volumes.

With its proprietary X-Y cross table, KERN Evo delivers maximum precision in a small installation space. The design allows maximum smoothness and excellent surface finish (Ra < 1 μm) even at high speeds and acceleration values.

Short distances between components and drives ensure minimal angle errors, while ultra-high resolution direct measuring systems guarantee maximum repeat accuracy in a working space of 300 x 300mm. KERN Evo can be optionally equipped with a 4th and 5th axis without compromising the stability and high precision of the basic machine.

With high quality components in all peripheral modules and easy automation, KERN Evo is widely used for unmanned 3-shift production in all industries that demand maximum precision on the workpiece.

Advanced technologies for maximum precision

The incorporation of sophisticated, mature technologies makes KERN Evo perfect for highly stable serial production tasks:

– Production with minimal positional variance due to a positional accuracy of ± 0.5 μm

– Interfaces to all commercial automation

-Intelligent thermal management for optimal temperature control of the spindle and cooling lubricant

– Perfect ergonomics with full access to the working space as well as free access to the mounting area

Related Searches

- CNC machining center

- Vertical CNC machining center

- Precision CNC machining center

- CNC milling machine

- 5-axis CNC machining center

- Vertical CNC milling machine

- High-precision CNC machining center

- High-productivity CNC machining center

- Column type CNC machining center

- CNC machining center with pallet changer

- Precision CNC milling machine

- Compact CNC machining center

- Machining center for the automobile industry

- 5-axis CNC milling machine

- High-precision CNC milling machine

- CNC machining center with moving table

- Medical CNC machining center

- CNC milling machine with pallet changer

- CNC milling machine for the mold industry

- CNC milling center for the mold industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.