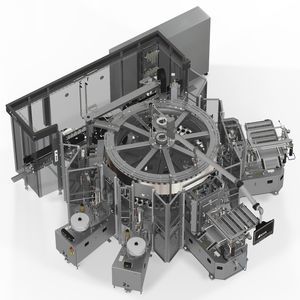

Automatic labelling machine Innoket Neo SKfor bottlesfor the beverage industryfor self-adhesive labels

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Product application

- for bottles

- Applications

- for the beverage industry

- Type

- for self-adhesive labels

- Other characteristics

- continuous-motion

- Throughput

35,000 p/h, 60,000 p/h

Description

The Innoket Neo SK is the perfect system for premium labeling applications. With the help of printed transparent film labels, for instance, you can give your containers a direct print or ‘no-label’ look. Labels like these open up a whole range of design and marketing options for a strong, high-quality brand image at the point of sale. Whether processing conical or cylindrical containers, PET, glass or cans the station is suitable for practically all shapes and materials. The maximum output is 60,000 bottles per hour for glass and PET containers and 35,000 containers per hour for cans.

Well thought out

In its tandem version the Innoket Neo SK also processes self-adhesive applications in uninterrupted autochange mode. As an option we also offer a camera-controlled container alignment for label placement. When used for beverage cans the machine can be flexibly placed either upstream or downstream of the filler for either full or empty cans.

Convincing

• Continuous, interruption-free operation with the double station array (tandem version)

• Maximum efficiency for your production process

• Less operator involvement thanks to non-stop operation (tandem version)

• Labeling of full or empty beverage cans – thus flexible positioning before or after the filler

Sustainable

• Low energy consumption thanks to cutting-edge components

• Compatible with returnables when wash-off self-adhesive labels are used

• Can be integrated into existing lines

VIDEO

Catalogs

No catalogs are available for this product.

See all of KHS GmbH‘s catalogsRelated Searches

- Industrial robot

- Automatic filler

- Articulated robot

- Liquid filler

- 6-axis robot

- Automatic labelling machine

- Bottle filler

- Palletizer

- Bottle labeling machine

- Shrink wrapper

- Automatic sleeve wrapping machine

- Complete packaging line

- Automatic palletizer

- 3-axis robot

- Layer palletizer

- Robotic palletizer

- SCARA robot

- Palletizing robot

- Automatic complete packaging line

- Labeller for the beverage industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.