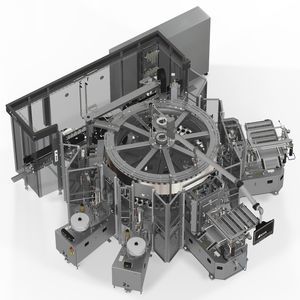

Automatic labeling machine Innoket Neo KLfor the beverage industrycold-glue

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Applications

- for the beverage industry

- Type

- cold-glue

- Throughput

74,000 p/h

Description

The Innoket Neo KL cold glue labeling station masters the full range of paper labeling tasks. Using the cold glue method body, shoulder, neck and back labels in many different formats are efficiently and reliably applied to your containers. The cold glue station can even process aluminum bottle neck foils without any trouble whatsoever. The maximum output is 74,000 bph.

Well thought out

The robust design of the Innoket Neo KL has many advantages, such as low-wear components and extremely quiet operation. KHS thus gives a warranty of no less than 20,000 hours until the first inspection. The machine can be used for both returnable and non-returnable containers. Another advantage is that thanks to the use of a camera-controlled alignment system labels can be precisely aligned to match attractive bottle reliefs.

Convincing

• High maintenance intervals of up to 20,000 hours of operation until servicing

• Little vibration makes labeling extremely quiet and low on wear

• Low operator involvement thanks to the automatic cleaning system and optional automatic label magazine

Sustainable

• Label material made of renewable raw materials (paper)

• Economical glue consumption

• Low use of cleaning agents (cleaning mostly possible with warm water)

VIDEO

Catalogs

No catalogs are available for this product.

See all of KHS GmbH‘s catalogsRelated Searches

- Industrial robot

- Automatic filler

- Articulated robot

- Liquid filler

- 6-axis robot

- Automatic labelling machine

- Bottle filler

- Palletizer

- Bottle labeling machine

- Shrink wrapper

- Automatic shrink wrapper

- Complete packaging line

- Automatic palletizer

- 3-axis robot

- Layer palletizer

- Robotic palletizer

- SCARA robot

- Palletizing robot

- Automatic complete packaging line

- Labeller for the beverage industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.