- Machine-tools

- Cutting Tool

- Steel cutting tool

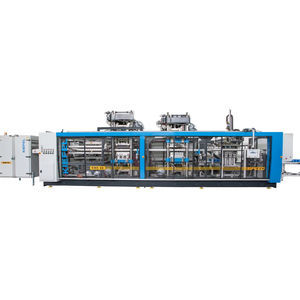

- Kiefel GmbH

Steel cutting tool

Add to favorites

Compare this product

Characteristics

- Treated material

- for steel

Description

With more than 40 years thermoforming technology experience in the packaging industry (cups, trays, blisters, etc.), Kiefel Packaging offers its customers customized tools of the highest quality. Everything to achieve one goal: your satisfaction and the unique productivity advantage.

We are always looking for the balance between production output, film utilization, easy tool handling and the shortest change over times. We excel through versatility and flexibility, delivering a productivity advantage and the best possible product to our customers.

Kiefel Packaging develops and builds tools for steel rule cutting applications - separate forming and cutting - and combined forming / cutting tools, suitable for all standard steel rule cutting machines and plastic materials such as PP, PS, PE, (R)PET, PLA etc.

We build thermoforming tools for all common thermoforming systems.

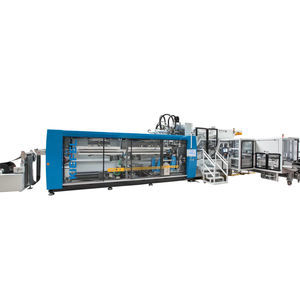

Forming/Cutting tools

The Kiefel Cut-in-Place (BFS) system enables the production of high-quality plastic packaging with the best price-performance ratio.

These tools are perfect for making trays and lids.

Your Kiefel Benefits:

• High cutting accuracy, even for materials with different shrinkage

• Cutting knives do not need to be positioned

• Low tool costs compared to the conventional forming/cutting system, since no costly profile grinding of the cutting contour is required

• Short equipping times: adjustment of a separate cutting station and the time required for changing blades and the punched counterplate is eliminated

• High flexibility: all common materials can be processed

• Low space requirements: no need for a separate cutting station

Catalogs

No catalogs are available for this product.

See all of Kiefel GmbH‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.