Ball bearing bearing 3 seriesradialaxialangular-contact

Add to favorites

Compare this product

Characteristics

- Rolling element

- ball bearing

- Configuration

- radial, axial, angular-contact, double-row

- Material

- steel

- Applications

- for the aeronautical industry

- Inside diameter

Min.: 30 mm

(1.18 in)Max.: 215 mm

(8.46 in)- Outside diameter

Min.: 10 mm

(0.39 in)Max.: 100 mm

(3.94 in)- Width

Min.: 14.3 mm

(0.563 in)Max.: 82.6 mm

(3.252 in)

Description

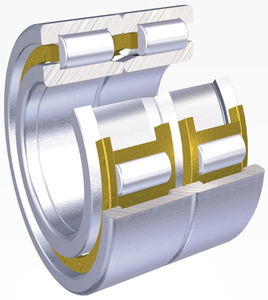

The double-row angular contact ball bearings correspond to their construction and function to a pair of single-row angular contact ball bearings turned by back to back, forming an „O“ shape. Both rings have a relatively deep raceways and they cannot be dismantled. In case of „E“ type construction, there is a filling opening on one side.

The bearings achieve high load rate due to the optimal ball size and their contact with raceways. They can effectively bear radial and axial load in both directions and they are suitable for relatively high rotation frequencies. The mounting of the "E" type construction bearings should be done in such a way, that the axial force is spread on the row of balls on the side opposite to the filling opening.

The raceways of the double row angular contact ball bearings are constructed in such way, that the flow lines of the contact points between balls and rings intersect the axis of the bearing outside the bearing itself ( contact angle α = 32°). This way the bearings can transfer the tilting point in the axial plane. Thus if there is limited space for mounting of the turning part, one bearing is sufficient.

The boundary dimensions of double row angular contact ball bearings indicated in the dimension tables correspond to the international dimensional plan ISO 15.

The designation of the bearings in the basic design is indicated in the dimension tables. The difference from the basic design is designated by additional symbols according to STN 02 4608.

Double row angular contact ball bearings with covers on both sides are produced with cover sheets (2ZR), or seals (2RSR).

Catalogs

Rooling bearings

30 Pages

Related Searches

- Rolling bearing

- Steel bearing

- Ball bearing bearing

- Roller bearing

- Radial rolling bearing

- Axial rolling bearing

- Single-row bearing

- Deep groove ball bearing

- Double-row bearing

- Precision bearing

- Cylindrical roller rolling bearing

- Tapered roller bearing

- Angular-contact bearing

- High-speed bearing

- Industry bearing

- Stainless steel rolling bearing

- Sealed bearing

- Thrust bearings

- Spherical bearing

- Combined bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.