Ball bearing bearing 61 seriesradialaxialdeep groove

Add to favorites

Compare this product

Characteristics

- Rolling element

- ball bearing

- Configuration

- radial, axial, deep groove, single-row

- Material

- rubber

- Other characteristics

- sealed, miniature

- Inside diameter

Min.: 19 mm

(0.75 in)Max.: 420 mm

(16.54 in)- Outside diameter

Min.: 10 mm

(0.39 in)Max.: 300 mm

(11.81 in)- Width

Min.: 5 mm

(0.197 in)Max.: 56 mm

(2.205 in)

Description

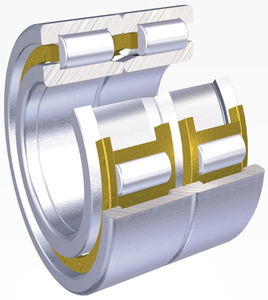

The single row deep groove ball bearings have relatively deep raceways on both rings without a filling slot and are non-separable. High load ratings are achieved by optimum ball sizes and by their conformity to the raceways. They can carry axial and radial loads in both directions and are suitable even for high rotational speeds. These bearings are manufactured in a broad assortment and are the most common rolling bearing type.

The table section are processed basic bearing parameters for the following subgroups:

• Miniature Bearings

• Thin walled Bearings 618 and 619 Series

• Standard assortment 160, 60, 62, 63 and 64 Series

Boundary dimensions of the single row deep groove ball bearings given in the dimension tables with the exception of separable single row ball bearings of types E and BO, correspond to the international standard ISO 15. The snap ring groove dimensions comply with the international standard ISO 464.

The single row deep groove ball bearings with sealing on one or on both sides are manufactured with metallic shields (Z, -2Z or ZR, -2ZR) or with seals (RS, -2RS or RSR, -2RSR). Bearings with shields have a non-contact sealing. The bearings are manufactured in the original design with steps for shields on the inner ring (Z, -2Z) or, in the new design, with a shield and a smooth rib on the inner ring (ZR, -2ZR).

The sealing rings made of rubber, vulcanized on metallic reinforced rings, provide an effective friction type seal. The bearings are manufactured in the design with rounded steps on the inner ring (RS, 2RS) or, in a new design, with a seal and a smooth rib on the inner ring (RSR, -2RSR).

Catalogs

No catalogs are available for this product.

See all of KINEX-KLF‘s catalogsRelated Searches

- Rolling bearing

- Steel bearing

- Ball bearing bearing

- Roller bearing

- Radial rolling bearing

- Axial rolling bearing

- Single-row bearing

- Deep groove ball bearing

- Double-row bearing

- Precision bearing

- Cylindrical roller rolling bearing

- Tapered roller bearing

- Angular-contact bearing

- High-speed bearing

- Industry bearing

- Stainless steel rolling bearing

- Sealed bearing

- Thrust bearings

- Spherical bearing

- Combined bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.