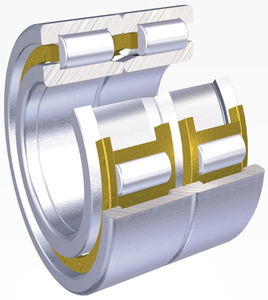

Ball bearing bearing angular-contactsingle-rowsteel

Add to favorites

Compare this product

Characteristics

- Rolling element

- ball bearing

- Configuration

- angular-contact, single-row

- Material

- steel, ceramic, brass

- Other characteristics

- high-speed

- Inside diameter

Max.: 120 mm

(4.72 in)Min.: 0 mm

(0 in)- Outside diameter

Max.: 250 mm

(9.84 in)Min.: 18 mm

(0.71 in)- Width

Max.: 120 mm

(4.724 in)Min.: 10 mm

(0.394 in)

Description

Single-row angular contact ball bearings for high rotation frequency and high accuracy of seating differ from normal angular contact ball bearings by inner design of bearing rings, by value of contact angle between ball and normal raceways of rings, by workmanship of cage and by high precise tolerance class of running.

The bearings are non-separable and their suitable seating arrangement assures required firmness and accuracy of housing. Bearings with ceramic balls are manufactured for extreme high speed with requirements for low friction and low heat generation in bearing, which gives less lubrication demands and higher lifetime of seating.

KINEX BEARINGS, a.s. delivers the single-row ball bearings with contact angles of α = 10°, α = 12°, α = 15°, α = 25° and α = 26°.

The bearings have special textile cage guided by inner ring (TB) or by outer ring (TA). Part of assortment has the massive brass cage guided by inner ring MB. Bearings with contact angle of α = 10° (designation B72.. CBTB and B72.. CBTA) have been designed for shaft support in grinding electro-spindles. The bearings are manufactured in tolerance class P4 according to the STN ISO 492, or in tightened tolerance class P4A (bearings of the P4A tolerance had been formerly delivered with additional TPF 1148 designation).

The bearings with contact angle of α = 12° (designation B70... CATB and B72.. CATB) and those with α = 26° (designation B70... AATB and B72.. AATB) have been designed for rotation seating of spindles and headstocks of tool machines and similar high-speed machines that require high accuracy of seating.

Catalogs

No catalogs are available for this product.

See all of KINEX-KLF‘s catalogsRelated Searches

- Rolling bearing

- Steel bearing

- Ball bearing bearing

- Roller bearing

- Radial rolling bearing

- Axial rolling bearing

- Single-row bearing

- Deep groove ball bearing

- Double-row bearing

- Precision bearing

- Cylindrical roller rolling bearing

- Tapered roller bearing

- Angular-contact bearing

- High-speed bearing

- Industry bearing

- Stainless steel rolling bearing

- Sealed bearing

- Thrust bearings

- Spherical bearing

- Combined bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.