- Industrial machines and equipment

- Heat Exchanger and Refrigeration

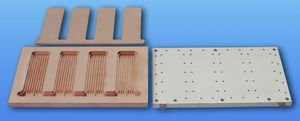

- Liquid-cooled cold plate

- KINTO ELECTRIC CO., LTD.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Liquid-cooled cold plate ACP-1aluminumcopper

Add to favorites

Compare this product

Characteristics

- Technology

- liquid-cooled

- Material

- aluminum, copper

Description

KINTO produces various liquid cooled heat sinks / cold plates with technologies of high precision CNC machining and friction stir welding (FSW).

The FSW technology provides solid state joint with mechanical properties similar to the parent materials, which results in a monolithic structure to achieve very strong hermetic seal.

The high performance heat sinks offer efficient way to manage electronic systems with highly concentrated power and heat.

The heat sinks can be produced with copper or aluminum alloy, with surface treatment such as nickel plating for copper or aluminum, or anodizing for aluminum.

The tests include X-Ray checking of welding quality, tightness test (leakage test), flow resistance test, thermal resistance test, temperature-rise test under different power, heat sink efficiency test and simulation test of heat sinks for different application conditions.

Kinto heat sink features:

- fine machined heat sink body and surface with high accuracy

- low pressure drops

- dual-sided cooling capability

- possibility of large heat sink size

- compatibility with industry accepted coolants

- friction stir welded joints for excellent non-leakage and high pressure rating performance as well as high resistance to corrosion

Applications in:

- high-power electronics

- lasers equipment

- power drives

- medical equipment

- military and aerospace industries

Catalogs

No catalogs are available for this product.

See all of KINTO ELECTRIC CO., LTD.‘s catalogsOther KINTO ELECTRIC CO., LTD. products

Liquid-Cooled Heat Sinks

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.