- Machine-tools

- Machine Tool Accessory

- Motor-driven rotary table

- Kitagawa Europe

- Products

- Catalogs

- News & Trends

- Exhibitions

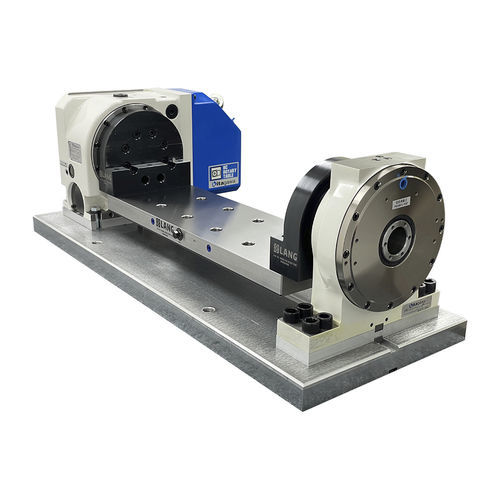

Motor-driven rotary table CB-Fhorizontalflexible

Add to favorites

Compare this product

Characteristics

- Operation

- motor-driven

- Configuration

- horizontal

- Other characteristics

- flexible

- Diameter

Max.: 96 mm

(4 in)Min.: 52 mm

(2 in)

Description

Very rigid system with a high assembly rotary clamping torque

High cutting torque allows for rapid machining of complex shapes

Quick.point holding force up to 6,000kgs ensures your work holding is secure

Built in Quick.point reduces the overall weight therefore lowering the moment of inertia

Clamping trunnion allows for excellent tooling access and mulitiple workholding options

Precision ground adaptors ensures high repeatability and for multiple trunnion positions or types

A clever single-sided trunnion designed for flexible work holding

The CB-F production system unites the rigidity and strength of KITAGAWA rotary tables with the rapid change flexibility of LANG Quick.point zero- point products, to produce the ultimate single-sided trunnion solution for modern manufacturing. LANG Quick.point is the lowest manually actuated zero-point system on the market thus building this technology directly into the 'bridge' of the trunnion system provides an immediate advantage over a traditional trunnion system.

The reduced height in the Z-Axis maximises the machining envelope and allows for many more work holding options when compared to a standard 'blank' trunnion specification with multiple plates fixed on top of each other.

The CB-F production system also has the option to be transformed from an off-centre position to an on-centre position which allows for work pieces to be presented to the machine spindle with a different aspect. If necessary the reverse side can utilised by drilling and tapping mounting holes for further workholding to be mounted.

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.