- Production Machines

- Other Manufacturing Equipment

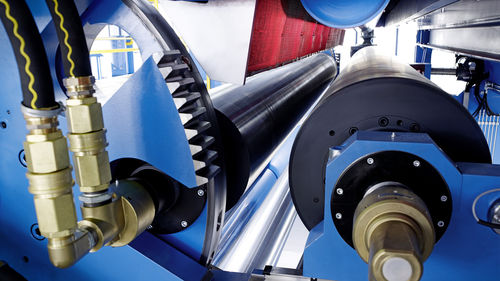

- Manual embossing unit

- KKA GmbH Kleinewefers Kunststoffanlagen

Rotary embossing unit manual

Add to favorites

Compare this product

Characteristics

- Options

- rotary, manual

Description

Due to the special design (turret-type) of the calender with turret disks that are directly mounted in the calender frame, the nip forces are completely absorbed by the calender frame. Unlike to a design involving an axis of rotation, there are no additional bending moments. Thus an absolutely consistent embossing result is achieved.

With this embossing calender, it is possible to carry out pattern changes within 2 minutes. The new embossing roll is moved into the right position by the turret disks. This is enabled by means of a central cooling water connection and a pneumatic coupling.

Moreover, inactive embossing rolls can be removed from the Bosstec during production so that downtimes are reduced to a minimum.

The KKA turret-type embossing calender is available in three different configurations. The first includes a turret unit with two embossing rollers, here one roller is in use and the second is in stand-by position. In the second configuration, the core piece of the calender consists of a turret unit with three embossing rollers (two embossing rollers in stand-by position). Finally, the third configuration features a turret unit with four embossing rollers allowing you to exchange one of the three embossing rollers in stand-by position.

Catalogs

No catalogs are available for this product.

See all of KKA GmbH Kleinewefers Kunststoffanlagen‘s catalogsOther KKA GmbH Kleinewefers Kunststoffanlagen products

Embossing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.