- Detection - Measurement

- Position, Speed and Acceleration Measurements

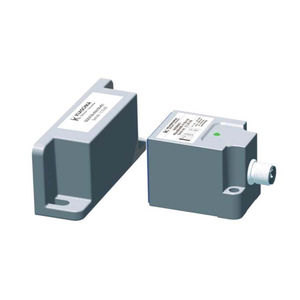

- Position detector

- KLASCHKA Industrieelektronik

Position detector WINDENT/P seriesRFID

Add to favorites

Compare this product

Characteristics

- Detected entity

- position

- Technology

- RFID

Description

Task Limit switches, which are operated by cams attached to the moving part of the machine, are frequently used for easy po-sition detection of linear or rotary movements in machines and systems. In this case it is only possible for the machine control system to assign the limit switch signal definitely to the position if a separate limit switch is used for each posi-tion. By using transponder-based WIDENT/P sensors, which e.g. in safety engineering are known as non-contact SIDENT safety switches, it is possible to detect several different posi-tions with only one sensor. A further advantage in this case is insensitivity to dirt, maladjustment and manipulation and the avoidance of components susceptible to wear

. Function and configuration Transponder-based actuating elements are attached to the moving part of the machine instead of the operating cams with the result that the WIDENT/P, which is mounted on the stationary machine part, can detect the actuating elements and read their intrinsic information as they move past. A spe-cific code is assigned to each of the actuating elements so that the WIDENT/P’s position detector can detect which ac-tuating element is currently within its reading range based on the code. An associated output switching signal which can be processed in the machine control system is generated in the WIDENT/P in line with the information read out.

Catalogs

Other KLASCHKA Industrieelektronik products

RFID Identification

Related Searches

- Proximity switch

- Cylindrical proximity switch

- Inductive proximity switch

- Distance sensor

- Compact detector

- Threaded proximity switch

- Rectangular proximity switch

- Analog distance sensor

- Rotational speed sensor

- Magnetic speed sensor

- Cylindrical distance sensor

- M30 proximity switch

- Capacitive proximity switch

- Non-contact proximity switch

- Hall effect speed sensor

- Non-contact velocity sensor

- Inductive distance sensor

- Universal detector

- PSD detector

- Double metal sheet detector

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.