• Design conforming to FEM and DIN norms

• Lifting and propulsion engine reducers made in EU (Optional)

• Lifting height which can be adjusted by rotary limit switch

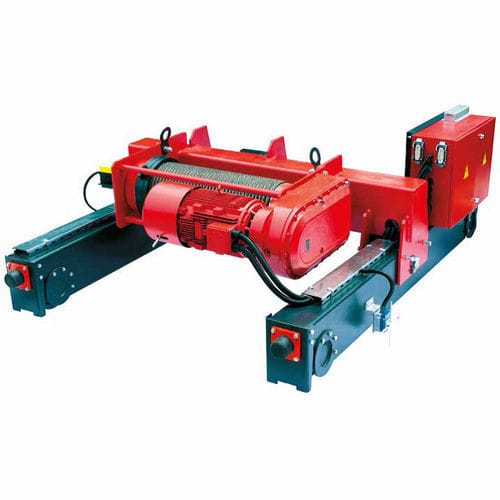

• Modular design easily changeable as per girder width

• Gear design suitable for silent operation

• Galvanize coated bolt, nut and similar fasteners

• Gears and wheels hardened by thermal treatment

• Sanding treatment against corrosion

• Special design rope guide protecting the rope and drum

• As the output shafts of lifting and propulsion reducers are being opened as router interlaced as per DIN 5480, safer load carrying feature compared to wedged system

• Manual break release rod enabling the easy release of brake even in case of power failure

• Special design electrical panel

• Standard connection with socket

• Spiral isolated cable protection hose protecting the cable from external factors

• 1 layer primer and 2 layers finish application

• Optionally, ability to operate at required speed ranges by the frequency inverter

• Load cell feature and overload limit switch increasing the lifetime and reliability of the crane by preventing it from operating with a load over its lifting capacity

• Special design minimizing the elevation difference in between two rails