- Power Transmission - Mechanical components

- Actuator and Positioning System

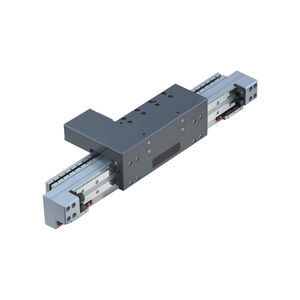

- Linear positioning stage

- KML Linear Motion Technology GmbH

Linear positioning stage LMS M seriesmotorized2-axisprecision

Add to favorites

Compare this product

Characteristics

- Orientation

- linear

- Type

- motorized

- Number of axes

- 2-axis

- Other characteristics

- precision, compact, high-speed

- Stroke

175 mm, 400 mm

(6.89 in, 15.748 in)- Speed

4.8 m/s

(15.75 ft/s)- Repeatability

3 µm

- Load

10 kg

(22.05 lb)

Description

• PnP cycle < 0.4 seconds

• 100 million cycles maintenance-free

• Highly rigid

The standardised LMS M 2-axis system has two axes arranged crosswise, which are directly connected to each other for mass optimisation. The highly compact, integral and inherently rigid design can be used for both upright applications (Z/Y axes) and horizontal cross-table applications (X/Y axes).

Masses of up to 5 or 10 kg can be positioned with maximum dynamics and the utmost precision. Depending on the application, the system can be supplemented with optional weight balancing and a holding brake. Numerous applications are possible, thanks to the extensive range of options.

With the innovative further development in the form of the LMS M Advanced, freedom from maintenance has been increased by a factor of 20, whereby this also includes wear parts such as guides, cables, etc. With the improved LMS M Advanced model series, up to 100 million cycles can be guaranteed maintenance-free. In addition, increased stroke lengths bring with them further possible applications.

• High-speed Pick & Place

• High-speed assembling

• Dispensing systems

• Feeding systems

• Handling technology

• Clock systems

• Test units (endurance test benches)

Catalogs

Other KML Linear Motion Technology GmbH products

Standard axes

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.