• Load capacity 15 times higher

• Rolled and ground manufacturing process

• Variable end machining

• Very quiet running

• Spindle diameter up to 210 mm

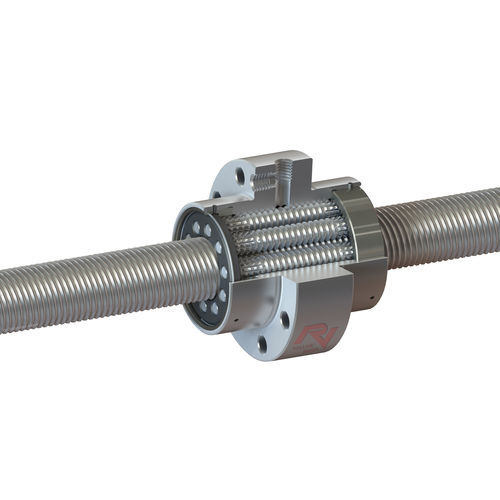

Thread rolling screw drives are machine elements for converting rotary movements into longitudinal movements and vice versa.

Instead of balls (as in conventional ball screws), thread rolls are arranged between the threaded spindle and the nut thread as rolling elements.

Due to the high number of contact points, these thread rolling screw drives can withstand loads many times higher (up to 15 times higher) than conventional ball screws. The product range includes threaded roller screw drives without roller feedback (type RV and HRV), inverted screw drives (RVI), differential screw drives (RVD) and threaded roller screw drives with roller feedback (type RVR) in various accuracy classes.

In supplement to this, we can also offer different bearing units for all designs, depending on the requirements of your application.

Advantages:

• High efficiency

• High axial load capacity

• No stick-slip effect

• Low space requirement

• Smooth and even running

• Low wear

• Long operating life

• High positioning and repetition accuracy

• Suitable for high speeds