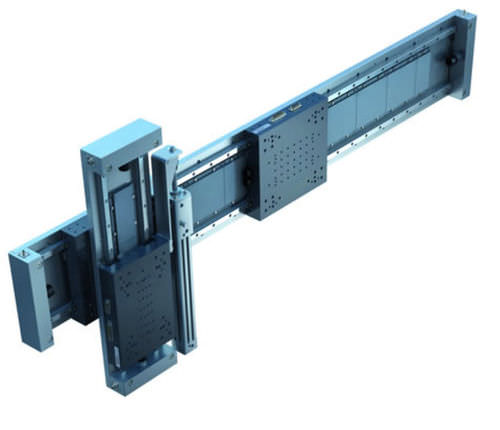

All standard linear motor systems as well as rotary tables can also be combined into multi-axis solutions. This includes, for example, XY cross tables, gantry systems, area gantry systems in different assembly variants, as well as cantilever systems.

To implement these combinations, KML offers a comprehensive and optimised range of connection elements. Depending on the series, these include adapter parts, flexure joints, components to compensate for temperature fluctuations, etc. Selection of the correctly dimensioned adapter parts takes place during the course of the system definition by your KML project contact.

Depending on customer requirements, the axis combinations can also include standardised energy chains, cables and lines. These add-on parts are assembled in a modular fashion in the course of project detailing according to your respective needs. To complement the supplementary components, qualified, standardised and tested servo controllers and motion controllers can be used, enabling the implementation of self-sufficient multi-axis solutions for almost unlimited fields of application.

As usual with all our standard linear motor systems, our multi-axis systems also come with the added value of factory commissioning and function testing.

When linear motor systems are combined to form multi-axis solutions, measurement by means of a laser interferometer is recommended, in particular where accuracy requirements are higher. Measurement can be carried out, for example, in the form of a factory acceptance test with a corresponding report. As a further option, the survey data can be made available for any compensation.