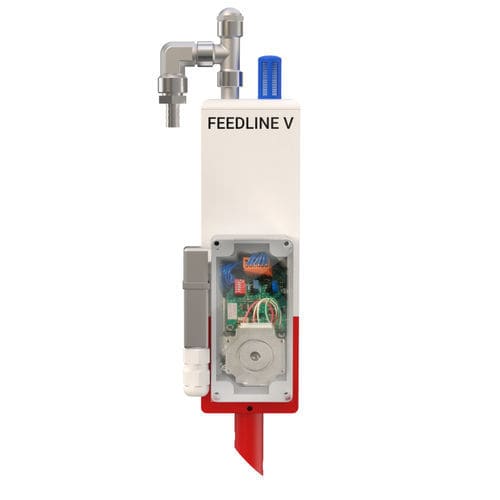

Abrasive metering FEEDLINE V monitor ensures optimized abrasive consumption for waterjet cutting tables.

Abrasive metering using the KMT Waterjet Feedline V abrasive garnet transfer system is the most popular abrasive handling machine with advanced features and seamless operation. This abrasive transfer vessel system ensures an efficient and reliable flow rate of abrasive materials during water jet cutting materials, enhancing productivity and precision in water jet cutting operations.

The KMT Waterjet FEEDLINE V Abrasive Metering System for controlling garnet flow rate advantages below.

Optimized Abrasive Consumption: The KMT Abrasive Metering System ensures precise control over abrasive feed rates, minimizing waste and maximizing efficiency in waterjet cutting, saving money in the cost of abrasive grit.

Stable and Repeatable Operating Parameters: The FEEDLINE V metering vessel provides consistent abrasive flow rates, essential for achieving high-quality cuts, particularly in brittle material applications.

Controlled Abrasive Supply: With the KMT FEEDLINE V system, a constant metered quantity of abrasive is supplied to the cutting head, preventing clogging of the mixing chamber and ensuring uninterrupted operation.

New Design for Maintenance Ease: The redesigned abrasive outlet and control unit feature simplified components, reducing maintenance requirements and enhancing system reliability.