- Production Machines

- Cutting Machine

- Laser cutting machine

- Knuth Machine Tools

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

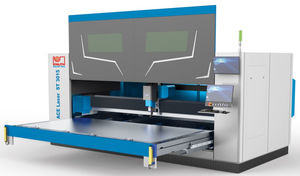

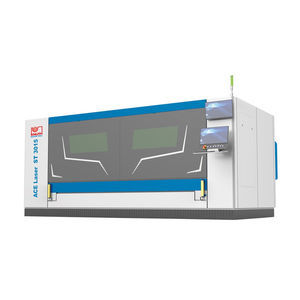

Laser cutting machine ACE.ST 3015 4.0Rfor metalsheet metalCNC

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Material

- for metal

- Product handled

- sheet metal

- Control type

- CNC

- Applications

- for industrial applications, for the automotive industry, for the electronics industry, for the aerospace industry

- Configuration

- compact

- Other characteristics

- precision, heavy-duty, linear, ISO

- X travel

1,530 mm

(60.24 in)- Y travel

3,050 mm

(120.08 in)- Z travel

100 mm

(4 in)- Laser power

4,000 W

- Repeatability

0.03 mm

(0.0012 in)- Overall length

4,750 mm

(187 in)- Overall width

2,260 mm

(89 in)- Height

2,100 mm

(83 in)- Weight

5,300 kg

(11,684.5 lb)

Description

The ACE.Laser ST series consists of advanced cutting systems that allow machining of large metal sheets in small spaces. All components are field tested and tuned perfectly for the cutting process. The machine configuration includes the complete cutting package with filtered vacuum exhaust. The pull-out table allows quick loading and unloading without taking up much space. These characteristics make the ACE-Laser the first choice for industrial laser cutting applications - from complex workpieces with lot size 1 to large-scale series productions in the electronics, aerospace or automobile industries.

Retractable cutting table for easy loading and unloading

Complete cutting package with filter extraction system

Comprehensive KNUTH service: installation, commissioning and maintenance

This state-of-the-art laser cutting system features a large 3000 x 1500 mm work area and fiber laser sources with 1500 to 6000 Watt beam power

For loading and unloading the work table can be pulled out from the machine’s full enclosure

The work table is mounted on a heavy-duty pull-out mechanism and easily can hold loads up to 1000 kg in the fully extended position

The torsionally rigid gantry spans across the long side of the work table and is moved synchronously on both sides

The machine meets perpendicularity or squareness tolerances for laser cutting acc. to DIN EN ISO 9013-1

The machine frame is made of a heat treated weldment ensuring tension-free construction and long-term repeatability for all cut parts

The precision linear guides require minimal maintenance and are designed for long-lasting precision and high cutting speeds

Catalogs

No catalogs are available for this product.

See all of Knuth Machine Tools‘s catalogsRelated Searches

- Knuth Machine Tools cutting machine

- Knuth Machine Tools metal cutting machine

- Knuth Machine Tools CNC cutting machine

- Knuth Machine Tools laser cutting machine

- Knuth Machine Tools cutting machine for industrial applications

- Automatic cutting system

- Knuth Machine Tools metal saw

- Knuth Machine Tools high-precision cutting machine

- Knuth Machine Tools sheet metal cutting machine

- Knuth Machine Tools automatic saw

- Circular sawing machine

- High-speed cutting system

- Knuth Machine Tools band saw

- Knuth Machine Tools precision cutting machine

- Wood sawing machine

- Knuth Machine Tools horizontal saw

- Knuth Machine Tools cutting machine for the automotive industry

- Knuth Machine Tools cut-off saw

- High-performance cutting system

- Knuth Machine Tools three-phase cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.