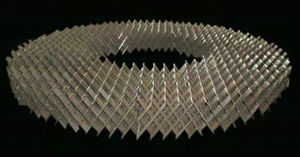

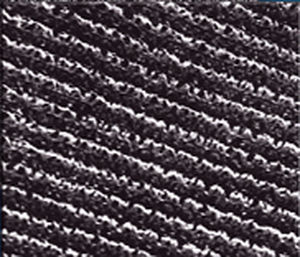

Distillation structured packing FLEXIPAC® HC®

Add to favorites

Compare this product

Characteristics

- Options

- for distillation

Description

Combines excellent capacity and efficiency characteristics with a lower pressure drop per theoretical stage.

FLEXIPAC® HC® structured packing has been used in hundreds of columns to increase capacity and reduce pressure drop for new construction and for replacing standard sheet metal structured packings, conventional random packings, and trays.

FLEXIPAC HC structured packing combines excellent capacity and efficiency characteristics with a lower pressure drop per theoretical stage. It is the preferred packing for vacuum distillation applications.

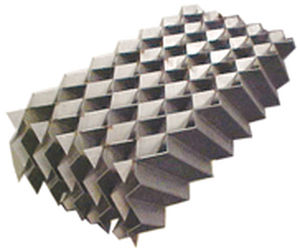

Similar in construction to FLEXIPAC® packing, FLEXIPAC HC packing has a modification in the geometry of the corrugation at the top and bottom for each packing layer. The change in geometry:

Eliminates the abrupt change in flow direction of the liquid and vapor phases at the packing layer interface.

Eliminates the premature build-up of liquid

Helps maintain the low pressure drop characteristics of structured packing throughout the efficient operating range

of the packing.

Catalogs

No catalogs are available for this product.

See all of Koch-Glitsch‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.