Liquids dispenser for distillation towers

Add to favorites

Compare this product

Characteristics

- Dispensed product

- liquids

- Other characteristics

- for distillation towers

Description

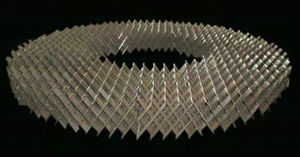

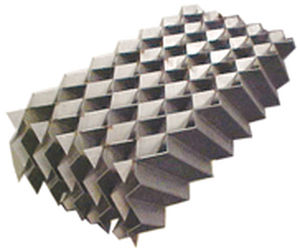

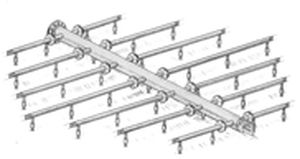

Packed tower columns use liquid distributors above each bed of packing to provide uniform liquid distribution. Redistribution of liquid between packed beds improves efficiency.

Liquid distribution

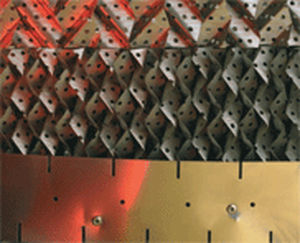

INTALOX® high performance distributors are designed to provide a uniform drip-point pattern and uniform point-to-point flow to the packing below. As a result, INTALOX high performance distributors are recommended for:

Distillation services

With high stage count per bed

That are operating near the minimum reflux ratio or close to an equilibrium pinch

Distillation systems

With low relative volatility

With high purity product

Absorption or stripping applications with close approach to equilibrium

Heat transfer applications with close approach temperatures

Koch-Glitsch “traditional” liquid distributors have less uniform distribution patterns and liquid flow than the INTALOX high performance distributors. The standardized construction of these distributors make them a more economical alternative for less demanding services, typically in conjunction with a conventional random packing.

Catalogs

No catalogs are available for this product.

See all of Koch-Glitsch‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.