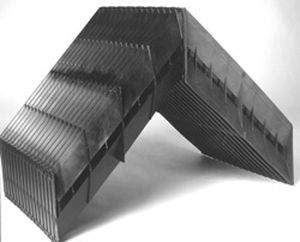

Smoke mist collector FLEXICHEVRON® Style VIIIoilfor desulfurization systems

Add to favorites

Compare this product

Characteristics

- Application

- smoke, oil

- Other characteristics

- for desulfurization systems

Description

Mist eliminators for electrical power producers, kilns, cement production, aluminum and other metal foundries, FCC units in refineries, and other power or process flue gases that require SO2 removal.

Processes for SO2 removal vary depending on the amount of SO2 involved, the solution used to absorb the SO2, and the particular equipment used in the absorption tower.

Applications with lower SO2 levels may need only one chevron level because of lower L/G ratios or other unique tower geometries.

The majority of applications use a mist elimination zone that contains two stages of mist eliminators.

Koch-Glitsch offers many types of chevron mist eliminators for the numerous styles of absorbers and internal support arrangements.

Catalogs

No catalogs are available for this product.

See all of Koch-Glitsch‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.