- Products

- Catalogs

- News & Trends

- Exhibitions

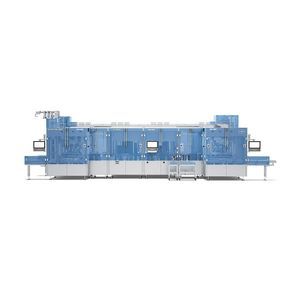

Camera inspection system Switch 350X-ray3Dautomatic

Add to favorites

Compare this product

Characteristics

- Technology

- camera, X-ray, 3D

- Operational mode

- automatic

- Type

- for defect detection

- Applications

- for the pharmaceutical industry

- Product applications

- for vials

Description

With our Switch 350, you benefit from the advantages of two machine concepts: We have combined the modularity, handling options and technologies of our well proven standard platforms with the flexibility of our small batch inspection machine to run syringes and vials on one and the same machine – with nesting system for syringes and vials alike.

Buy one inspection machine instead of two – and save up to 40% of investment.

For example, you fill syringes and have them inspected for particles, cosmetic defects, and leaks, and for pierced needle shields? Since the syringes are nested, you also need a de/renesting system for the inspection machine.

Another one of your products is filled into vials on the same filling line and is, of course, also inspected for particles, cosmetic defects and leaks.

This used to require two high-performance inspection machines, one for syringes and one for vials.

lOur Switch 350 is perfectly adapted to the market trend of flexible production lines where vials and syringes are filled alternately. You no longer need two inspection machines – just switch the format parts and get started.r

Rupert Depner, Area Sales Manager Inspection, Körber Business Area Pharma

VIDEO

Catalogs

No catalogs are available for this product.

See all of Körber Pharma‘s catalogsRelated Searches

- Inspection system

- Inspection machine

- Automated inspection system

- Camera inspection system

- Quality inspection system

- Automatic inspection machine

- X-ray inspection system

- Industrial inspection machine

- Defect detection inspection system

- Defect inspection machine

- Fast inspection system

- 3D inspection system

- Optical inspection machine

- Visual inspection machine

- Inspection machine for the pharmaceutical industry

- High-speed inspection machine

- Inspection system for the pharmaceutical industry

- Non-contact inspection machine

- Medical inspection machine

- Compact inspection machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.