- Products

- Catalogs

- News & Trends

- Exhibitions

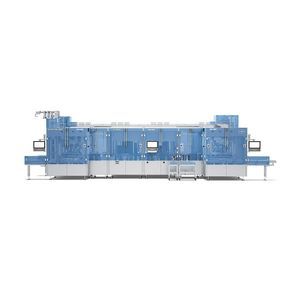

Non-contact inspection machine DE.SY.REopticalfor the pharmaceutical industrymedical

Add to favorites

Compare this product

Characteristics

- Technology

- optical

- Sector

- for the pharmaceutical industry, medical

- Other characteristics

- automatic, non-contact

Description

No glass-to-glass contact in your entire production process? Our DE.SY.RE is the inspection solution for you.

You know how important gentle handling of your containers is in production and therefore feed them into the machines in tubs and nests? If that’s the case, the Seidenader DE.SY.RE is the right inspection solution for your production process. Three modules, one system — all from a single source.

A de-nester at the inspection machine’s feed system lifts the containers out of the nest and gently places them into the infeed. In the process, the containers do not touch each other. There is also no friction, pressure or vibration during the inspection. At the inspection machine’s outfeed, a re-nester lifts the containers back into the nest. No glass breakage, no air bubbles in the product — this is how you minimize the downtimes of your production line as well as the false rejection rate.

"The goal during the development of our DE.SY.RE was to achieve especially gentle feeding of the containers, completely without glass-to-glass contact. De-nester and re-nester are optimally tailored to the inspection machine and all components are perfectly matched with each other. These are the preconditions for ideal inspection results."

Your benefits

No glass-to-glass contact

No glass breakage, no machine downtime. No vibrations, no air bubbles, no false rejects

Perfectly matched

Three components, one system. Perfectly matched — from the planning to hand-over: everything from a single source

Fast

Up to 600 containers per minute picked up, inspected and reinserted: the DE.SY.RE meets every challenge

VIDEO

Catalogs

facts

24 Pages

Related Searches

- Inspection machine

- Automatic inspection machine

- Industrial inspection machine

- Defect inspection machine

- Optical inspection machine

- Visual inspection machine

- Inspection machine for the pharmaceutical industry

- High-speed inspection machine

- Non-contact inspection machine

- Medical inspection machine

- Compact inspection machine

- Inspection machine for the cosmetics industry

- Vial inspection machine

- Semi-automatic inspection machine

- Particle inspection machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.