- Products

- Catalogs

- News & Trends

- Exhibitions

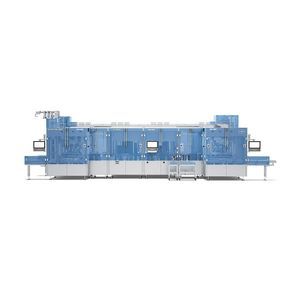

Optical inspection machine EVEindustrialautomatic

Add to favorites

Compare this product

Characteristics

- Technology

- optical

- Sector

- industrial

- Other characteristics

- automatic

Description

Our mobile and flexible lab unit EVE provides you with the settings of up to 14 camera stations for the simulation of your production environment. Gain data and insights to optimize your existing process and products or develop new ones.

Lab tests under industrial conditions: EVE enables you to simulate all of the inspection parameters of our fully automatic inspection machines on an extremely small footprint. Thanks to a turret for four different camera lenses as well as adjustable camera angles, you only need two stations to depict 14 camera stations of an automatic inspection machine — without interrupting the ongoing production process.

And EVE can do lots more. In fact, the platform’s claim is: “Turn seeing into knowing.” That’s because all data and images of product features and defect properties collected during test runs are stored and are available for analyses as well as for customized reports and documentation. This enables you to compare results and interpret them more easily.

In case of increased reject rates of your fully automated machine, our lab unit can also augment the images of defects in order to further increase the precision of our AI-based deep-learning software Eject-X. Thus you permanently build up knowledge that helps you optimize existing products and processes and develop new ones.

Your benefits

Versatile inspection

14 camera stations to simulate the inspection of your high-performance machine on one square meter

Reproducible conditions

Conducting tests under production conditions accelerates product development

Automated data analysis

Automatic collection and processing of data makes results more comparable

VIDEO

Catalogs

No catalogs are available for this product.

See all of Körber Pharma‘s catalogsRelated Searches

- Inspection machine

- Automatic inspection machine

- Industrial inspection machine

- Defect inspection machine

- Optical inspection machine

- Visual inspection machine

- Inspection machine for the pharmaceutical industry

- High-speed inspection machine

- Non-contact inspection machine

- Medical inspection machine

- Compact inspection machine

- Inspection machine for the cosmetics industry

- Vial inspection machine

- Semi-automatic inspection machine

- Particle inspection machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.