- Products

- Inspection module

- Körber Pharma

- Products

- Catalogs

- News & Trends

- Exhibitions

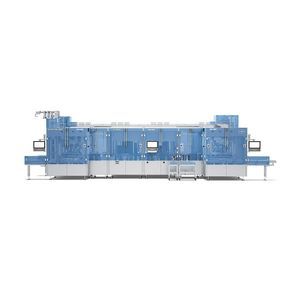

Inspection module UpsideDown

Add to favorites

Compare this product

Description

Do you have a product that has somewhat different handling requirements than most others? Our special handling module for camera inspection and leak detection (HVLD) easily masters unusual challenges.

Change of perspective

Persistent droplets at the stopper or the shoulder of a vial may be misinterpreted by cameras. Reduce your false reject rate: Our Seidenader UpsideDown rotates the vial 180° for inspection. Liquid covers the stopper and the shoulder – the droplets are gone, so are the false rejects.

It can also be advantageous for the general stopper inspection, if the vial is turned upside down. We will gladly determine the appropriate handling for your containers and products.

Leak detection for low fills or viscous products

Do you want to check containers with low fill levels for leaks? The UpsideDown module is the right solution for this purpose. The critical closure and shoulder areas are safely tested upside down in the carousel. For comprehensive leak testing, two additional HV stations are integrated in the module, over which the container is guided while standing upright to inspect the sidewall and the bottom of your product.

Viscous products in ampules pose a particular challenge for leak inspection. In an ampule that is upright or lying on its side, the contents cannot spread to the tip for the interior to be sufficiently wetted with liquid. That’s why for high-voltage testing our Seidenader UpsideDown turns the ampule upside down and rotates it to distribute the contents from the tip to the entire sidewall. In this way, we enable every product to be reliably checked for leaks.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Körber Pharma‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.