- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

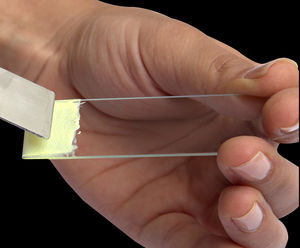

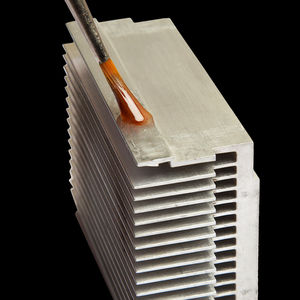

Epoxy adhesive KB 1686 Mfor metalfor plasticsglass

Add to favorites

Compare this product

Characteristics

- Chemical composition

- epoxy

- Type of substrate

- for metal, for plastics, glass, for ceramics

- Number of components

- two-component

- Technical characteristics

- thermally-conductive, electrically-conductive, chemical-resistant, shear strength, water-resistant

- Applications

- for electronics, for bonding, sealing, for coating, for OEM

- Working temperature

Min.: -50 °C

(-58 °F)Max.: 120 °C

(248 °F)

Description

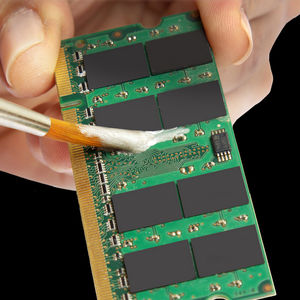

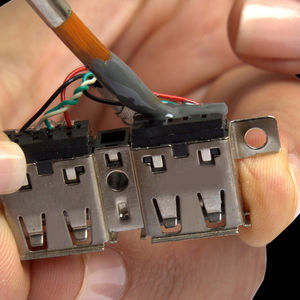

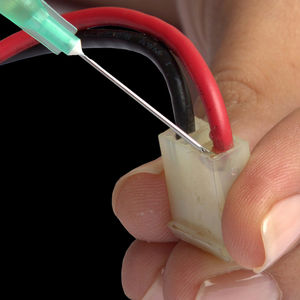

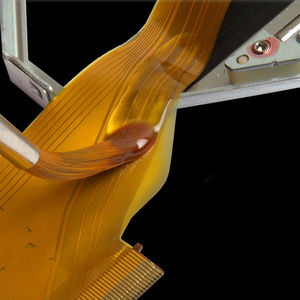

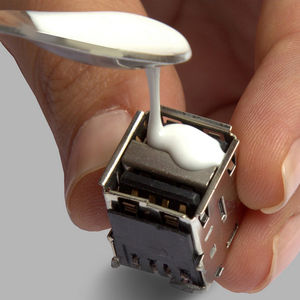

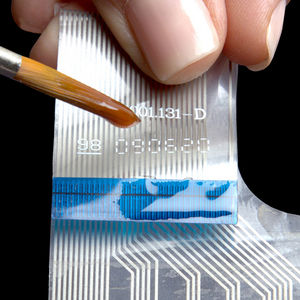

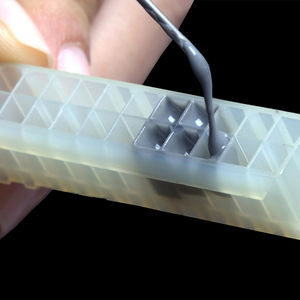

Kohesi Bond KB 1686 M is a two component, nickel filled epoxy system suitable for bonding, coating and sealing. It has a convenient 1:1 (Part A: Part B) mix ratio by weight or volume. Firstly, it offers very good electrical conductivity and dimensional stability. This epoxy system readily cures at room temperature and can achieve faster cures at elevated temperatures. The optimal cure schedule is an overnight room temperature set-up followed by a heat cure at 70°C – 90°C for 3 – 5 hours.

KB 1686 M offers a volume resistivity of 5 – 10 ohm-cm. It is ideal for use in static dissipation and EMI/RFI shielding applications. It offers an extensive serviceable temperature range. It is an outstanding adhesive that offers superb physical strength properties, allowing it to adhere well to a wide variety of substrates including metals, ceramics, most plastics and glass. In addition to superior electrical and thermal conductivity (1.3 – 1.4 W/m/K), it also offers astounding chemical resistance to various cleaning agents, oils and water. Part A and Part B are gray in color. It has a thixotropic paste like consistency and a very low coefficient of thermal expansion (CTE). Owing to its versatile performance, KB 1686 M is widely used in electronics, aerospace, electrical, semiconductor, microwave and many OEM applications.

Product Highlights

Easy mix ratio of 1:1 by weight or volume

Outstanding dimensional stability

Superior thermal conductivity

High lap shear strength (> 2 100 psi)

Nickel filled

electrically conductive

100% solids system

Typical Applications

Bonding

Sealing

Coating

Catalogs

No catalogs are available for this product.

See all of Kohesi Bond‘s catalogsRelated Searches

- Single-component glue

- Metal glue

- Industrial glue

- Plastic glue

- Glass glue

- Epoxy adhesive

- Dispersion adhesive

- Bonding glue

- Two-component glue

- Electronic glue

- Ceramic glue

- Sealing glue

- Fast curing glue

- Viscosity adhesive

- Conductivity adhesive

- Rubber adhesive

- Composite material adhesive

- High-temperature adhesive

- Automotive glue

- Coating adhesive

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.