- Materials - Tools - Components

- Semi-finished products

- Brazing paste

- Koki Company Limited

Solder paste S3X58-M500C-7for metalfor heat exchangers

Add to favorites

Compare this product

Characteristics

- Function

- solder

- Applications

- for metal, for heat exchangers

Description

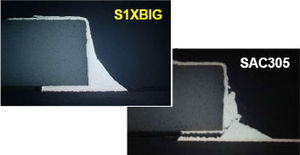

Good and Consistent Wetting

Spreading to Oxidized Metal Surface.

Activator Technique

After removal of oxide film at pre-heating stage, a new protective film formed on the surface of solder particles to effectively prevent re-oxidation during the remaining heating process thereby results in powerful wetting/melting.

Solder Spreading Property

After continual print, pause 45 min. or 60 min. and resume printing and observe print volume.

Test condition

・ Stencil : 200μm / 6.5mmφ aperture

・ Pre-conditioning : 150ºC for 16Hr

・ Heat source : Convection reflow

・ Reflow : Air

Product Performance Table

Product Name - S3X58-M500C-7

Product Category - Solder Paste

Composition - Sn 3.0Ag 0.5Cu

Melting Point(℃) - 217-219

Particle Size(μm) - 20-38

Viscosity(Pa.s) - 200

Flux Content(%) - 11.8

Halide content(%) - 0

Flux Type - ROL0 (IPC J-STD-004)

Optical Powder Size(μm) - 0

Catalogs

No catalogs are available for this product.

See all of Koki Company Limited‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.