- Materials - Tools - Components

- Semi-finished products

- Brazing paste

- Koki Company Limited

Solder paste S3X58-HF912

Add to favorites

Compare this product

Characteristics

- Function

- solder

Description

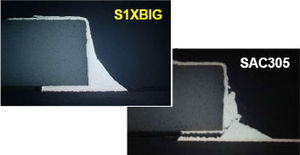

Solution for the Splattering

in Reflow Soldering

Mechanism of Flux Splattering & Anti-Splattering Technique

In the conventional solder paste, flux gas gets generated once the solder starts melting, and the flux entrapped in solder

gets discharged by increased inner pressure of molten solder, splattering flux or flux with solder around.

S3X58-HF912, in contrast, forms a flux layer on the surface of the molten solder and prevents splattering of flux or flux with solder while soldering.

Flux Splattering Test

The conventional solder pastes requires high pre-heat temperature to evaporate volatile flux components

which helps reduce the splatters during the reflow.

S3X58-HF912 successfully conforms to various reflow profiles thereby eliminating the need to increase

the pre-heat temperature to prevent occurrence of the flux splatters during the reflow.

Product Performance Table

Product Name - S3X58-HF912

Product Category - Solder Paste

Composition - Sn 3.0Ag 0.5Cu

Melting Point(℃) - 217-219

Particle Size(μm) - 20-38

Viscosity(Pa.s) - 190

Flux Content(%) - 11.5

Halide content(%) - 0

Flux Type - ROL0 (IPC J-STD-004A)

VIDEO

Catalogs

No catalogs are available for this product.

See all of Koki Company Limited‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.