- Materials - Tools - Components

- Semi-finished products

- Brazing paste

- Koki Company Limited

Solder paste S3X58-HF900Ncopperfor electrical componentshigh-temperature

Add to favorites

Compare this product

Characteristics

- Function

- solder

- Material

- copper

- Applications

- for electrical components

- Other characteristics

- high-temperature

Description

Super High Reliability Halogen Free

Solder paste

S3X58-HF900N

Sn 3.0Ag 0.5Cu

Designed to insure extremely high reliable SIR/ECM with an ultra narrow pattern

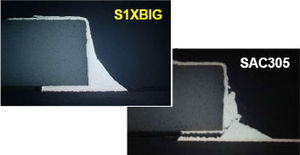

Reliability Challenges in Narrow Gap Patterns

When testing insulation reliability and flux residues, a 0.317mm gap comb coupon is normally used for both JIS and IPC standards. However, more and more customers are recently requesting a narrower gap test coupon.

■Issues

・Narrower gap allows metal ions to move between electrodes and increase electro migration.

・The above allows easier movement of ionized metal between tracks, thus increasing the occurence of electro migration.

■Solution

・The activator reducing system and hydrophobic rosin system in S3X58-HF900N prevents the formation of ionic metal.

This helps stop the occurrence of electro migration in very narrow tracks.

New Technology Achieves High SIR

■Conventional

Lowered insulation resistance due to the existence of ionic substances in the flux residue accelerates activity of the ionic substances.

Discharged metallic ion at the anode transfers to the cathode and gets reduced to a metal. The metallic deposit accumulates to form a dendrite at the cathode and shortens the distance between the electrode, resulting in ionic migration.

■S3X58-900N

With HF900N, less ionic substances remain in the flux residue. Due to the absence of ionic substances in the flux residue,

insulation resistance stays consistent even when a voltage is applied.

Notable Result in Narrow Gap SIR Test

S3X58-HF900N retains high SIR with no ionic migration observed after a 1000 hour applied voltage environment test.

Catalogs

No catalogs are available for this product.

See all of Koki Company Limited‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.