- Industrial machines and equipment

- Welding and Assembly

- Epoxy adhesive

- Koki Company Limited

Epoxy adhesive JU-90LT-3for plasticssingle-component

Add to favorites

Compare this product

Characteristics

- Chemical composition

- epoxy

- Type of substrate

- for plastics

- Number of components

- single-component

Description

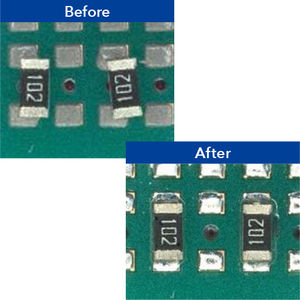

Reduces Thermal Stress

on the Components and Board

Low curing temperature mitigates damage

to the PCB and the components

JU-90LT-3 cures at low temperatures around 90-100℃, reducing

the level of oxidation for the components and substrate.

It enables improvement in the overall product quality and first time product quality.

[ Curing Condition and Bonding Strength ]

Stable dispense shape and height,

superior heat slump resistance

Dispense shape of JU-90LT-3 is stable during continuous dispensing.

The dispense shape and height after 10000 shots are practically the same as the initial shots.

Furthermore, the diameter of a dispensed adhesive was only approx. 4.7% larger after being cured at 90℃ for 90 sec.*

*according to our in-house test

[ Heat Slump Property / Curing condition: 90℃ x 90 sec. ]

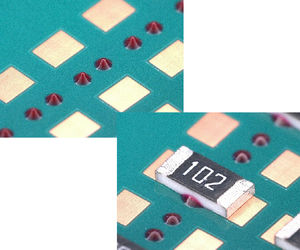

Excellent electrical reliability after curing, suitable for fine-pitch patterns

JU-90LT-3 after curing shows good surface insulation resistance, making it suitable for use in fine-pitch patterns.

In the biased humidity test with temp. 85℃ and humidity 85%,

JU-90LT-3 indicates good insulation resistance well after 1000 hours without any trace of electrical migration.

Catalogs

No catalogs are available for this product.

See all of Koki Company Limited‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.