- Materials - Tools - Components

- Semi-finished products

- Joint paste

- Koki Company Limited

Joint paste S3X58-HF1100soldercopperfor electrical components

Add to favorites

Compare this product

Characteristics

- Function

- joint, solder

- Material

- copper

- Applications

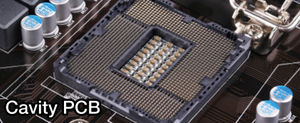

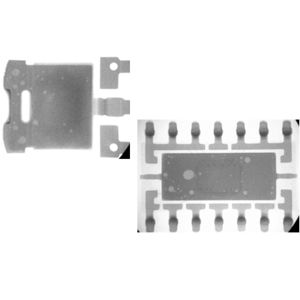

- for electrical components

- Other characteristics

- high-temperature

Description

A Solution to Just About All Soldering Requirements

S3X58-HF1100, by adopting newly developed techniques through our expertise and experiences, has gained excellent results in all soldering features such as wetting, ICT testing, flux splattering, voiding, printing, tackiness, electrical reliability, halogen free, etc.

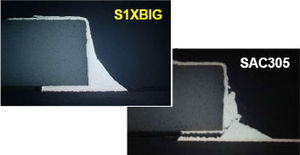

Powerful Wetting Technique Advances Solder Joint Reliability

S3X58-HF1100 has applied a newly engineered flux technology in which solder particles are protected from being oxidized by an easy-to-remove protective layer and the antioxidant in the flux suppresses continued oxidation over time.

Such effects help save the amount of activator needed for oxidation prevention, as well as the activator capping technique which allows maximum activation strength when the solder is molten.

Flux Coagulation Technique Improves First Pass Yield

The flux formulation of S3X58-HF1100 solder paste is specifically designed to exhibit enhanced flux coagulation at the time when the solder starts to melt.Instant coagulation and evacuation of the liquified flux when the solder gets molten, brings about various benefits in soldering performance such as reduction in voiding rate and flux splattering, and improved wetting and ICT properties.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Koki Company Limited‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.