- Materials - Tools - Components

- Semi-finished products

- Brazing paste

- Koki Company Limited

Solder paste T4AB58-HF seriessilver basedfor electrical componentshigh-temperature

Add to favorites

Compare this product

Characteristics

- Function

- solder

- Material

- silver based

- Applications

- for electrical components

- Other characteristics

- high-temperature

Description

Reliable and workable in

Low temperature reflow

Energy-saving whilst reducing thermal damage to components and board

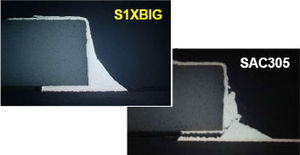

The melting temperature of T4AB58-HF360 is 138-140ºC, lower than SAC305 making it ideal for soldering heat-sensitive components and PCBs.

As the reflow profile can be set lower, the energy consumption can be reduced by approx. 40%.

Further, the less energy consumption contributes to lower CO2 emission.

New technology keeps the solder paste from drying for stable performance in continuous use.

The viscosity stability and tack time are also improved to ensure component retention during and after the component is placed.

Good wettability and low void performance

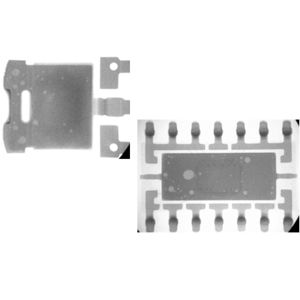

T4AB58-HF360 effectively prevents the occurrence of voiding at the solder joint with various

types of components such as QFN/BTC, Pwtr, chip component, etc.

Low voiding is ensured even when the printed / dispensed solder paste is left on the board for

a longer period of time before component placement and reflow.

Catalogs

T4AB58-HF360

1 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.