- Materials - Tools - Components

- Semi-finished products

- Brazing paste

- Koki Company Limited

Solder paste S3X70-G835copper basedsilver basedfor electrical components

Add to favorites

Compare this product

Characteristics

- Function

- solder

- Material

- copper based, silver based

- Applications

- for electrical components

- Other characteristics

- high-temperature

Description

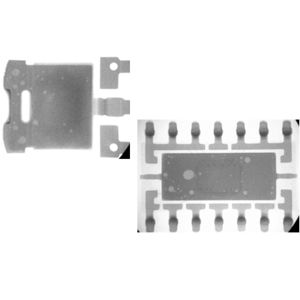

Applicable to 0402 chip component

with AIR reflow atmosphere.

Reduces defects during stencil printing

with a newly developed lubrication technique

S3X70-G835 adopts a type of non-volatile solvent as its primary constituent,

and can keep itself from drying when the paste is left idle.

A better print-to-pause property results,

ensuring a consistent printability and workability even after a 60-min. pause.

[ Print-to-pause property ]

Evaluate transfer rate of printed solder paste volume before and after leaving on a stencil.

・Substrate: FR-4 ・Stencil thickness: 0.08mm (laser cut)

・Stencil aperture: 0.18mm dia. Pattern ・Squeegee angle: 60°

Excellent meltability and wettability

on micro-patterns in air reflow

Although the size of the S3X70-G835 solder particle is Type 5,

the product exhibits good meltability and wettability without a Nitrogen atmosphere.

This has been enabled by a newly engineered flux formulation optimized for Type 5 powders.

[ Reflow test in Air atmosphere ]

・Substrate: FR-4 ・Stencil thickness: 0.08mm

・Stencil aperture: 0.175mm dia. , 0402R

・Aperture ratio: 100% ・Pad surface finish: Cu-OSP

・Heating method: Hot air reflow ・Reflow atmosphere: Air

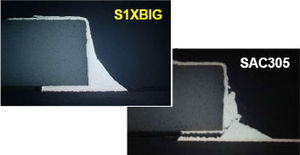

Reduced voids with various board surface

finish treatments

In addition to having good melting properties,

S3X70-G835 displays excellent wetting performance on various board surface finishes.

This helps the molten solder to quickly push out flux elements,

and reduces the occurrence of voids as a result.

Product Performance Table

Catalogs

No catalogs are available for this product.

See all of Koki Company Limited‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.