- Materials - Tools - Components

- Semi-finished products

- Joint paste

- Koki Company Limited

Joint paste SB6N58-M500SIsoldersilver basedfor electrical components

Add to favorites

Compare this product

Characteristics

- Function

- joint, solder

- Material

- silver based

- Applications

- for electrical components

- Other characteristics

- high-temperature

Description

Highly thermal stress resistant alloy with indium

Increasing demand for high thermal stress durability

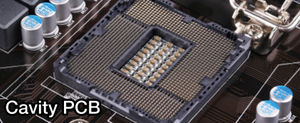

For PCBs exposed to severe temperature fluctuation, long term durable alloys are required to counter thermal cycling induced stress.

■ Mechanism of crack occurrence by thermal cycling stress

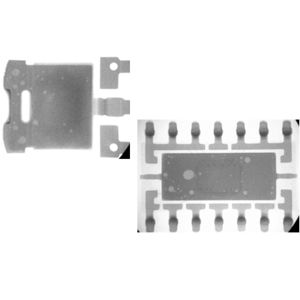

Absorption of mechanical stress by addition of indium

SB6N58 M500S1 adopted 6% indium to balance and optimize thermal stress and deformation character̶ istics, which could occur if excessively added.

■ Difference of deformation temperature by Indium content

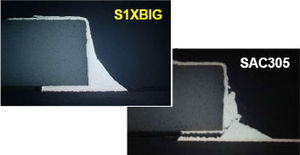

Remarkable joint reliability

■ Shear strength ( 40⇔ 150°C for 30min. each) & Cross sectional view (After 1500 cycles)

Product Performance Table

Product Name

SB6N58-M500SI

Product Category

Solder Paste

Composition

Sn 3.5Ag 0.5Bi 6.0ln

Melting Point(℃)

202-210

Particle Size(μm)

20-38

Viscosity(Pa.s)

200

Flux Content(%)

11.1

Halide content(%)

0

Flux Type

ROL0

Characteristics

for Dispense : SB6N58-M500SID

Catalogs

No catalogs are available for this product.

See all of Koki Company Limited‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.