- Products

- Catalogs

- News & Trends

- Exhibitions

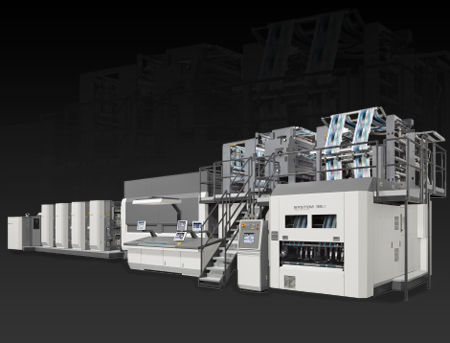

Web-fed offset press SYSTEM 35Sfor paper

Add to favorites

Compare this product

Characteristics

- Type of printing

- web-fed

- Other caracteristics

- for paper

- Plate length

570 mm

(22 in)- Plate width

900 mm

(35 in)

Description

Optimized performance in a single-size blanket-cylinder web design, the System 35S is a powerful solution for a broad work mix. The best-selling web in Japan.

Automatic plate-changing of all eight plates in just two minutes when configured with Full-APC*, which speeds up job changeover, ensures high mounting precision, enables one-step print startup, and offers parallel execution of changeover tasks.

The B4 x 2P feeder (for pinless, clear-cut sheets) is a new type (air transport) that raises high-speed stability.

Equipped with the KHS-AI (Advanced Interface) as standard equipment. The press thus effectively achieves shortened makeready time and a reduction in waste paper. Also, equipping the press with AI-Link* (integrated control system that covers peripheral devices) and Smart Sequence allows for a further reduction in waste paper and shorter makeready time. (*Optional specification)

Related Searches

- Printing machine

- Color label printer-applicator

- Paper label printer-applicator

- Automatic label printer-applicator

- Offset printing machine

- Rotogravure printing machine

- High-speed label printer-applicator

- Sheet fed offset printing machine

- Paper trimmer

- Paper offset press

- 4-color printing machine

- In-line label printer-applicator

- Programmable paper cutter

- 6-color printing machine

- 8-color printing machine

- Web-fed offset printing machine

- 2-color printing machine

- Double-sided label printer-applicator

- Hydraulic paper cutter

- 2-color offset press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.