- Products

- Catalogs

- News & Trends

- Exhibitions

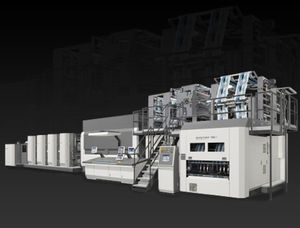

Web-fed offset press SYSTEM 40for paper

Add to favorites

Compare this product

Characteristics

- Type of printing

- web-fed

- Other caracteristics

- for paper

- Plate length

646 mm

(25 in)- Plate width

1,060 mm

(42 in)

Description

Development of double-size blanket cylinder series of presses was based on maximizing productivity (through higher maximum operating speed), improvement of short-run performance to level of single-size cylinder presses, improvement of print quality by means of common design philosphy, and strengthened customer support. Double-size blanket cylinder ensures high print quality at the maximum operating speed due to high structural rigidity.

Two models offer the choice of 800rpm or 1,000rpm.

Automatic platechanging of all 8 plates in just two minutes when configured with Full-APC*.

Wide lineup of folders allows Komori to configure machines with specifications and performance for specific users.

Equipped with the KHS-AI (Advanced Interface) as standard equipment. The press thus effectively achieves shortened makeready time and a reduction in waste paper. Also, equipping the press with AI-Link* (integrated control system that covers peripheral devices) and Smart Sequence allows for a further reduction in waste paper and shorter makeready time. (*Special specification)

Related Searches

- Printing machine

- Color label printer-applicator

- Paper label printer-applicator

- Automatic label printer-applicator

- Offset printing machine

- Rotogravure printing machine

- High-speed label printer-applicator

- Sheet fed offset printing machine

- Paper trimmer

- Paper offset press

- 4-color printing machine

- In-line label printer-applicator

- Programmable paper cutter

- 6-color printing machine

- 8-color printing machine

- Web-fed offset printing machine

- 2-color printing machine

- Double-sided label printer-applicator

- Hydraulic paper cutter

- 2-color offset press

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.