- Products

- Dynamic rope

- Konecranes

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

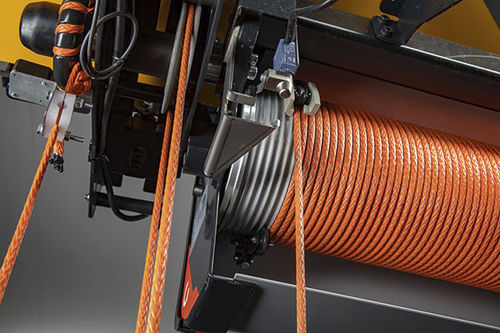

Dynamic rope textile

Add to favorites

Compare this product

Characteristics

- Type

- dynamic

- Material

- textile

Description

A bold new approach

In 2019, we launched the Konecranes S-series hoist with synthetic rope instead of traditional steel wire rope. Since then we've sold hundreds of S-series hoists to customers around the world who are thrilled with the cleanliness and durability. And we just recently introduced a low headroom version of the popular S-series hoist and the revolutionary Konecranes X-series crane.

We’re the first company to produce overhead cranes with synthetic rope as a default and we’ve put it through extensive lifetime tests to ensure safety, strength and durability. The synthetic rope we use in our hoists is made with Dyneema®—one of the world’s strongest fibers—which has been used for more than 30 years in demanding rigging applications such as lifting slings, mooring and towing large sea vessels. Lives also depend on it during search and rescue operations and mountain climbing. So keep reading to learn all about synthetic rope and how it compares to steel rope.

Strong and durable

The synthetic rope has a 12-strand non-rotating structure that is hollow inside. The stable structure of the rope removes or substantially reduces the risk of certain rope defects that steel ropes are prone to like birdcaging, waviness, core protrusion and kinks.

And while steel rope has multiple variations such as rotation resistant, heavy duty, left and right hand, galvanized and stainless steel, or for different lubrication—there is only one variation of the synthetic rope to fit the same applications.

The lightweight rope is easy to handle and doesn't fray or produce sharp barbs, minimizing the risk of cuts on the hands of anyone handling the rope.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Konecranes‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.