- Production Machines

- Other Manufacturing Equipment

- Processing line

- Körber Technologies GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

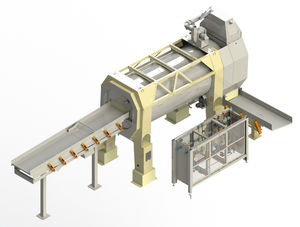

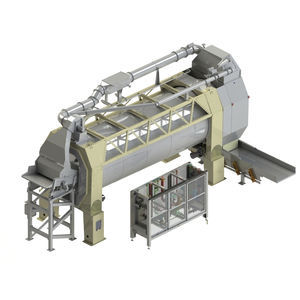

Drum type processing plant HAUNI Tobcon-Mfor tobacco stem

Add to favorites

Compare this product

Characteristics

- Options

- drum type, for tobacco stem

Description

HAUNI Tobcon-M is redefining tobacco processing with advanced features that boost efficiency and quality. By effectively increasing stem moisture, it enhances roller and cutter performance, resulting in improved filling power and yield with minimal degradation. Its ability to reduce material loss during cutting further ensures consistent, high-quality results.

The system excels in delivering uniform stem conditioning, adapting seamlessly to different product requirements. Its innovative design ensures that even the thickest stems are conditioned evenly, maintaining product integrity and quality throughout the process.

Tobcon-M is designed for ease of operation and high availability. Simplified access and intuitive process monitoring reduce cleaning efforts and minimize downtime, keeping productivity high. Adjustable settings allow for flexible processing, while optional features, such as additive spraying, further expand its versatility.

Efficiency and sustainability are central to Tobcon-M’s design. With a focus on energy-saving operations and lightweight construction, it reduces operational costs and environmental impact. The system’s quiet operation and streamlined maintenance make it an ideal choice for modern manufacturing environments.

HAUNI Tobcon-M combines innovation, adaptability, and eco-conscious design to meet the evolving demands of tobacco processing. Contact us today to learn how it can transform your production capabilities!

Other Körber Technologies GmbH products

Primary: conditioning & casing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.