- Products

- Storage and handling system

- Kortlever (Technisch Buro Kortlever B.V.)

Storage and handling system for the food industry

Add to favorites

Compare this product

Characteristics

- Options

- for the food industry

Description

Universal applicator for:

Grated cheese

Cubed meat or fish

Vegetables

Walnuts and sliced almonds

Whole and half walnuts

Raisins, etc.

Configuration:

Hopper

Rotating rakes with lower belt

Mobile C-form frame construction stand alone

Easy to clean with liquids because of the foldable and removable parts

Constructed in stainless steel 304 as well as high-grade and food-grade plastics

Optional: product conveyor / recovery system / target strewer

Standard working width: 400 – 600 – 800 – 1.000 – 1.200 mm

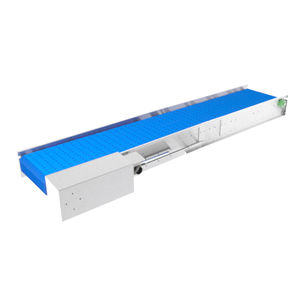

Panning systems for loading of trays, peel boards as well as proofing belts, ovens and frying oven.

Panning lengths: 1.000 – 1.200 – 2.000 – 3.000 – 3.600 mm

Working widths: 400 – 600 – 800 – 1.000 – 1.200 – 1.500 mm, as a special up to 3.600 mm

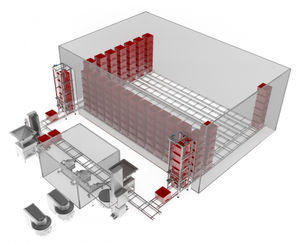

Paternoster final proofing installation for tin bread straps, baking trays and peel boards.

Paternoster cooling installation for trays.

Paternoster inline buffer system for tin bread straps, baking trays and peel boards.

Automatic loading and unloading of racks with trays.

Capacity: up to 20 dough racks/1.000 trays/hr.

Proofing systems for racks, with automatic rack infeed, isolated housing and air conditioning.

Capacity: up to 20 dough racks/1.000 trays/hr.

Steam system for racks with automatic rack infeed, with isolated housing.

Air conditioning for racks with automatic rack infeed, with isolated housing.

Cooing by means of air circulation with air in- and outfeed.

Catalogs

No catalogs are available for this product.

See all of Kortlever (Technisch Buro Kortlever B.V.)‘s catalogsOther Kortlever (Technisch Buro Kortlever B.V.) products

BREAD PROCESSING

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.