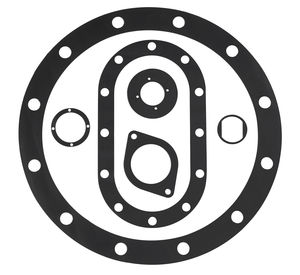

Custom-made Bakelite

Add to favorites

Compare this product

Characteristics

- Other characteristics

- custom-made

Description

Bakelite is a material based on the thermosetting phenol-formaldehyde resin. Bakelite products have unique properties of low density with high dimensional stability, surface hardness, gloss heat resistance to corrosion and electrical insulation properties.

Bakelite is phenol-formaldehyde resin binder mixed with fillers like wood flour, fibrous cellulose, graphite, mica and glass fibre. Against the properties, the fillers are selected. KPM has the facility to mold Bakelite parts for specific products made to bond with the rubber

With a team of experts and decades of experience, KPM has been excelling in Bakelite molding for 2 decades now. KPM has incorporated its facility and a skilled team of technicians to manufacture bakelites with 100% inspection and on-time delivery.

Bakelite is a material based on the thermosetting phenol-formaldehyde resin binder mixed with fillers like wood flour, fibrous cellulose, graphite, mica and glass fibre. Due to their unique properties of low density with high dimensional stability, surface hardness, gloss heat resistance to corrosion and electrical insulation properties, they are in demand to every sector.

In addition to assuring the technical stability of bakelite parts, KPM has installed the automation technique to bond the bakelite to rubber and other compatible composites. We have an expert team of chemists develop parts where the adhesive is precisely applied and certified of its desirable properties. Against the properties, bakelite bonding can also be applied to rubber as well as the other substrates as desired.

Catalogs

No catalogs are available for this product.

See all of KPM Plasto Rubber Co.‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.