- Packing - Handling - Logistics

- Conveying

- Belt conveyor

- Kraken Automation

- Products

- Catalogs

- News & Trends

- Exhibitions

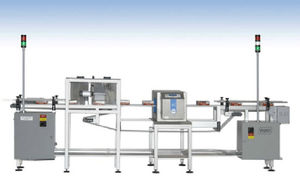

Belt conveyor horizontalinspectiondiverter

Add to favorites

Compare this product

Characteristics

- Technology

- belt

- Form

- horizontal

- Function

- inspection, diverter

- Construction

- gravity

- Transported product

- bag, carton, for trays

Description

System Highlights

• Removes defective products from inspection systems or splits products into multiple lanes

• Ideal for lines with limited horizontal space

• Non-contact system eliminates product damage

• Can reach speeds in excess of 300 ppm

The High-Speed Reject/Diverter system takes a single lane of randomly spaced products and splits them into two vertical lanes or into a reject system without relying on gravity – ideal for removing defective products from inspection systems or splitting products into multiple lanes where horizontal space is at a premium.

This non-contact system can reach speeds in excess of 300 ppm. The system allows the operation to recover products that would otherwise go to waste. It is easily integrated into various inspection systems such as checkweighers, metal detectors, x-ray machines, seal checkers, vision systems, and volume checkers.

The system does not require any external forces to reject or divert products from the packaging line, in contrast to typical reject and divert mechanisms such as mechanical divert arms, air reject, or pneumatic rejects. Reliability and repeatability are ensured while maintaining product integrity when using this non-contact equipment.

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveyor for the food industry

- Roller rail conveyor

- Inclined conveyor

- Drag chain conveyor

- Food conveyor

- Stainless steel conveyor

- Materials handling conveyor

- Modular conveyor

- Pallet rail conveyor

- Feeding conveyor

- Transfer rail conveyor

- Discharge conveyor

- Curved rail conveyor

- Case conveyor

- Carton conveyor

- Conveyor for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.