- Packing - Handling - Logistics

- Conveying

- Chain conveyor

- Kraken Automation

- Products

- Catalogs

- News & Trends

- Exhibitions

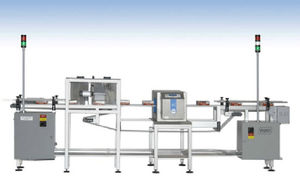

Chain conveyor KLB03-200mergedistributionfeeder

Add to favorites

Compare this product

Characteristics

- Technology

- chain

- Form

- merge

- Function

- distribution, feeder, diverter

- Transported product

- bag, carton, for trays

- Sector

- for the food industry

- Other characteristics

- stainless steel, aluminum, sanitary

Description

System Highlights

• Product merging or distribution at rates from 150 up to 400 units/min

• High speed product gating system, allowing product routing for closely spaced (minimum gap of 1”) product in transit

• Simple, rugged machine concept using tabletop conveyor

• Machine framing available in extruded aluminum or stainless steel construction

• Apply a variety integrated industry accepted controls

• Additional options for extended sanitary applications

From a product merging and redistribution standpoint, the KLB03-200 is the answer to selecting, diverting, and merging product on high-speed production lines where proper product phasing and gapping is crucial.

The KLB03-200’s multiplexing functionality is achieved when it diverts product from one or more source lane(s), then redistributes the product to one or more destination lane(s): selecting, diverting, and merging at measured intervals to ensure correct product interlacing following gapped placement.

Correct gapping and interlacing effectively allows for increased production in that the downstream machines are kept evenly stocked with product. The speed of upstream feeder stations, due to lack of stoppages, can now be incrementally increased; this allows for an increase in throughput without any significant additional expenditures required.

APPLICATIONS

• Cereal bags

• Cracker slugs

• Frozen food trays

• Small to medium size cartons

• And more!

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveyor for the food industry

- Roller rail conveyor

- Inclined conveyor

- Drag chain conveyor

- Food conveyor

- Stainless steel conveyor

- Materials handling conveyor

- Modular conveyor

- Pallet rail conveyor

- Feeding conveyor

- Transfer rail conveyor

- Discharge conveyor

- Curved rail conveyor

- Case conveyor

- Carton conveyor

- Conveyor for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.