- Packing - Handling - Logistics

- Conveying

- Belt conveyor

- Kraken Automation

- Products

- Catalogs

- News & Trends

- Exhibitions

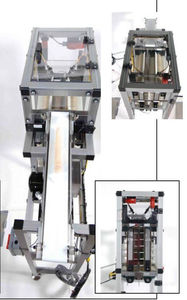

Belt conveyor KSI3T-110transfercompactpackage

Add to favorites

Compare this product

Characteristics

- Technology

- belt

- Function

- transfer

- Construction

- compact

- Transported product

- package, bag, for trays

- Sector

- for the food industry

Description

System Highlights

• 110 frozen, wrapped PPM

• Up to 220 products/min achievable when multiple infeed system lanes are configured

• 3-axis system (per infeed lane)

• Compact transfer footprint space 3’ X 3’ X 5’ (based on cartoner bucket infeed elevation)

• Two-stage infeed conveyor assembly providing consistent product delivery and staging to collation area

• Three-stage collation gate array providing a range of package counts per customer requirements (2–6 count)

• Integral product tamping and squaring mechanisms to ensure repeatable package transfer

• Pneumatic product transfer shock containment to prevent bounce back during transfer

• Operator interface for product selection, system controls, and alarm display

• Controls and operator interface configured to customer standards

Kraken Automation’s KSI3T-110 Infeed and 3-Stage Collation/Transfer System is a versatile system engineered to deliver, pre-collate, and transfer frozen wrapped product synchronously to a cartoner infeed system.

Each Product Infeed/Collation/Transfer System can achieve speeds of 110 infeed products per minute, or 220 per minute on a single cartoning machine configured with two infeed and collating/transfer lanes.

Using a vertical array of high-speed, motion-controlled collation gates, frozen wrapped products can be gradually collated and squared to a given pack format in counts ranging from 2-6 packets. The specified number of packets, based on product thickness and customer requirements, is prepared for synchronous transfer to a continuous motion packaging system (cartoner).

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveyor for the food industry

- Roller rail conveyor

- Inclined conveyor

- Drag chain conveyor

- Food conveyor

- Stainless steel conveyor

- Materials handling conveyor

- Modular conveyor

- Pallet rail conveyor

- Feeding conveyor

- Transfer rail conveyor

- Discharge conveyor

- Curved rail conveyor

- Case conveyor

- Carton conveyor

- Conveyor for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.