- Packing - Handling - Logistics

- Conveying

- Belt conveyor

- Kraken Automation

- Products

- Catalogs

- News & Trends

- Exhibitions

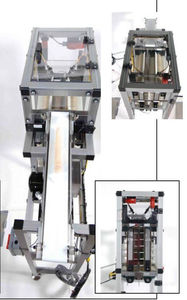

Belt conveyor KCSIT-220curvedaccumulationtransfer

Add to favorites

Compare this product

Characteristics

- Technology

- belt

- Form

- curved

- Function

- accumulation, transfer

- Construction

- compact, wide

- Transported product

- bag, for cans, carton

- Sector

- for the food industry, for packaging lines

Description

System Highlights

• 220 CPM (Cans Per Minute) on single infeed transfer lane

• Single axis system (per infeed lane)

• Compact transfer footprint space 6’ X 3’ X 4’ (based on cartoner bucket infeed elevation)

• Integral high-speed can insertion stager to always load a can when a mated bag or pouch is present (no-bag, no-can)

• Guaranteed singulated-can delivery from upstream bidirectional accumulation table using Kraken configured magnetic infeed conveyor

• Easy sweep alignment and homing with mated cartoning machine

• Operator interface for product selection, system controls, and alarm display

• Controls and operator interface configured to customer standards

The Kraken KCSIT-220 is a unique mated-product infeed system that reliably feeds and inserts mixed, non-matching components into cartons or packets at high speeds. This system is the best on the market today. We are proud to optimize our customer’s packaging system operations while maintaining their zero-loss manufacturing mandates.

This high speed can infeed and transfer system can singulate, deliver, and mate cans with other bagged or pouched product at rates of up to 220 cans/min.

Moreover, our parallel-mounted, speed-matched, can-sweep system is equipped with a specialized staging assembly to load cans with a ‘no-bag, no-can’ guarantee, only delivering cartons or packets to downstream packaging operations when cans and their mate bags or pouches are both present.

APPLICATIONS

• Canned products such as:

• Fruit fillings

• Fish

• Meats

• Vegetables

• A wide range of added-component canned products

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveyor for the food industry

- Roller rail conveyor

- Inclined conveyor

- Drag chain conveyor

- Food conveyor

- Stainless steel conveyor

- Materials handling conveyor

- Modular conveyor

- Pallet rail conveyor

- Feeding conveyor

- Transfer rail conveyor

- Discharge conveyor

- Curved rail conveyor

- Case conveyor

- Carton conveyor

- Conveyor for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.