- Packing - Handling - Logistics

- Conveying

- Belt conveyor

- Kraken Automation

- Products

- Catalogs

- News & Trends

- Exhibitions

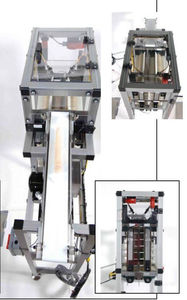

Belt conveyor KBIT-10transporthandlingtransfer

Add to favorites

Compare this product

Characteristics

- Technology

- belt

- Function

- transport, handling, transfer

- Construction

- compact, wide

- Transported product

- pallet, bag

- Sector

- for the food industry

- Maximum load

25 kg

(55.116 lb)

Description

System Highlights

• 10 BPM (Bags Per Minute) on single infeed transfer lane to main trunk

• Main trunk conveyor delivery rates up to 30 BPM to multiple robotic palletizing stations

• Compact transfer footprint space 4’ X 4’ X 4’ (based on trunk conveyor infeed elevation)

• Specialized transfer conveyor control to deliver bags from wide-edge leading to narrow-edge leading with no bag skew on transfer

• Simple articulating transfer actuating arm for easy maintenance

• Optional non-marking product identification systems available for downstream package or pallet selection

• Optional integrated operator interface for multiple bag transfer handling parameterization

• Controls and operator interface configured to customer standards

Kraken Automation’s range of infeed transfer systems extends to heavy packaged products weighing upwards of 55 lbs (25 kg). Our heavy bag infeed transfer system is designed to handle product in demanding industrial environments for a variety of heavy-duty packaging and robotic palletizing systems. The KBIT-10 is a unique bag transfer mechanism that transfers heavy mesh, paper, or plastic bags from filler conveyors to main trunk transport conveyors to robotic palletizing cells. The system orients the bags to present the wide edge leading to the main trunk transport conveyor and the narrow edge leading to the robotic palletizing cells. The KBIT-10 is a huge benefit to operations involving manual labor for bag handling and aids tremendously in reducing physical injuries prevalent in heavy-product work environments.

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveyor for the food industry

- Roller rail conveyor

- Inclined conveyor

- Drag chain conveyor

- Food conveyor

- Stainless steel conveyor

- Materials handling conveyor

- Modular conveyor

- Pallet rail conveyor

- Feeding conveyor

- Transfer rail conveyor

- Discharge conveyor

- Curved rail conveyor

- Case conveyor

- Carton conveyor

- Conveyor for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.