- Packing - Handling - Logistics

- Packing and Packaging

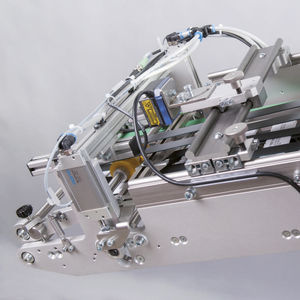

- Bottle packaging line

- Kraus Maschinenbau GmbH

Electronic component packaging line bottlemanual

Add to favorites

Compare this product

Characteristics

- Product applications

- for electronic components, bottle

- Other characteristics

- manual

Description

Manufacture of a safely transportable package for 3-D products.

Advantage

Automation can significantly rationalize the entire packaging process and also minimize packaging costs. Sleeved and shrunk products are protected for transportation in the best possible way and require no further packing or filling material. Even breakable goods such as bottles, electronic components and medicines are ideally protected and delivered to the customer intact.

Kunde

Internet chemist

Description of function

The JoKer friction feeder, located on the face side, feeds the cardboard packaging reliably onto the collator's studded conveyor belt. The carrier boxes are now fitted with the package contents, such as boxes for medicines, bottles, books, spare parts, machine components etc. and are transferred to the foil packaging machine. There, the products are wrapped in a foil sleeve and then shrunk in a shrink tunnel creating a secure package. The cardboard packaging with the shrunk products is then taken by a further studded conveyor belt and transported to the transfer unit. There, the cardboard packaging is folded and automatically pressed into the box moving past at a 90° angle. The barcode on the cardboard packaging and on the transport box can be verified before transfer.

Machine characteristics

• Sizes: 650 x 225 mm

• Speed between 10-20 cycles/min depending on packing stations

• 4 packing stations, expandable almost without limitation

Special designs

We are happy to work out for you the right concept and offer the appropriate solution for you. Please talk to our design department about the possibilities.

Catalogs

No catalogs are available for this product.

See all of Kraus Maschinenbau GmbH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.