- Products

- Inspection line

- Kraus Maschinenbau GmbH

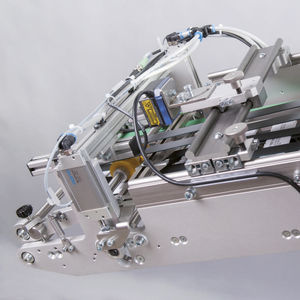

Box inspection line for pharmaceutical products

Add to favorites

Compare this product

Characteristics

- Product applications

- for boxes, for pharmaceutical products

Description

Folding boxes and enclosures are checked offline to ensure that they are of the same type and correct

Advantage

The machine's short tooling times and mobile design make it versatile and suitable for use at various stations. The integrated pharmaceutical scan and the pneumatic discharge provide

the system with maximum reliability. This is particularly in connection with hand packing places a meaningful and important addition for the" doublecheck".

Because of the special holder, the reading head can be moved easily without tools to every position above the product. The head can also be pivoted 90° so that even longitudinally-oriented codes can be read.

Description of function

The feeder separates the product reliably. A sensor then opens the reading gate for the scanner, and the product is checked. Work is undertaken in accordance with the pharmaceutical principle. Every product is initially a bad product and must to be read as correct. Good products are then taken from the transfer conveyor and transferred onto the shingle outfeed conveyor. Scaling and scale separation can then be set from 1-100 units. Bad products are discharged underneath via the pneumatic gate. A sensor is also installed in the gate as a countercheck.

Machine characteristics

• Sizes: min. 60 x 60 mm, max. 300 x 350 mm (depending on the feeder width)

• Max. speed 200 cycles/min (depending on the product)

• Cycled or continuous operation possible

• PLC control system with appropriate interfaces

• Ink jet system integration possible

Special designs

We are happy to work out for you the right concept and offer the appropriate solution for you.

Catalogs

No catalogs are available for this product.

See all of Kraus Maschinenbau GmbH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.