- Products

- Automatic gluing machine

- Kraus Maschinenbau GmbH

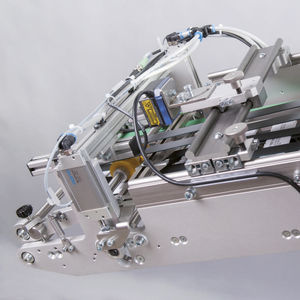

Automatic gluing machine TEfor the packaging industry

Add to favorites

Compare this product

Characteristics

- Options

- automatic

- Applications

- for the packaging industry

Description

Folding boxes are provided with tamper evident features in accordance with EU Directive 2011/62/EU and DIN EN 16679 via a gluing system. A special machine concept for the pharmaceutical industry was designed for this purpose, which is ideal for manual work stations, clinical trials and small lots.

Advantage

The machine's short tooling times and modular design make it versatile and economic to use. The combination of hot and cold glue achieves an irreversible join that prevents the folding box being opened without destroying this. The strap monitoring and automatic rejection gate guarantee a reliable production process.

Description of function

The filled and erected box is inserted on the finger conveyor on the front. The glue is applied while the box passes through. The special sensors that are integrated check whether the glue was actually applied. The TE straps are then wrapped around using the closing deflector system on both sides. This is checked again using special sensors. If something did not work when applying the glue or wrapping the TE closing straps around, the box is automatically rejected. The box is then pushed out into a rejection bin provided for this purpose. The sealed boxes are then transferred to the ownstream system.

Machine characteristics:

• Formats: min. 30x30x60 mm, max. 200x300x350 mm

• Speeds of up to 20 cycles per minute are possible

• High precision servo motor drive

• PLC control system with appropriate interfaces

• CRF 21 Part 11 functions

Options

• Printing systems can be integrated for serialisation

• Camera systems can be integrated

• Automatic product feeding with corresponding autonomy is possible

Catalogs

TE GLUELINE

3 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.