- Industrial machines and equipment

- Printing, Marking and Engraving

- Inkjet printing machine

- Kraus Maschinenbau GmbH

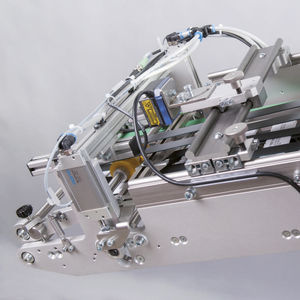

Inkjet printing machine modular

Add to favorites

Compare this product

Characteristics

- Printing technology

- inkjet

- Other characteristics

- modular

Description

Tablet blister packs are coded in the separated exit extension with an inkjet-system.

Advantage

The machine's short tooling times and modular design make it versatile and economic to use. The tablet blister packs are printed as they run through the feeder's separated run-out extension, where different printing and labelling systems can be used. Blister packs can be printed either on the tablet side or on the aluminium foil side. Printed blister packs are then transferred to a segment conveyor where products are stacked respectively. The number of units per product stack can be set using the control system. This ensures that stacks can be removed easily.

Description of function

Tablet blister packs are placed on the scaled feed belt. Inline transfer from another machine, positioned upstream, is also possible. A special separator then reliably separates the blister packs – both directions of travel are possible – tablet top side or bottom side. These are then printed as they run through the separated run-out extension. Printed blister packs are then transferred to a segment conveyor where they can be removed manually. If blister packs are not removed, a fill-level sensor stops the machine automatically as soon as the conveyor is full.

Machine characteristics

• Sizes: min. 30x 60 mm, max. 200 x 150 mm

• Speed when printing 60m/min

• Cycled or continuous operation possible

• PLC control system with appropriate interfaces

Special designs

We are happy to work out for you the right concept and offer the appropriate solution for you. Please talk to our project department about the possibilities.

Catalogs

No catalogs are available for this product.

See all of Kraus Maschinenbau GmbH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.