- Products

- Catalogs

- News & Trends

- Exhibitions

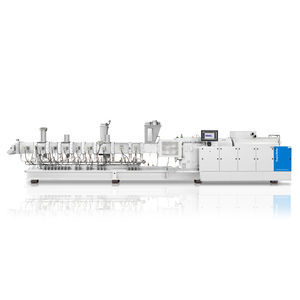

Pipe extrusion line IPCfor thermoplasticswith water coolingwith air cooling

Add to favorites

Compare this product

Characteristics

- Type

- for pipes

- Treated material

- for thermoplastics

- Other characteristics

- with water cooling, with air cooling, high-throughput

Description

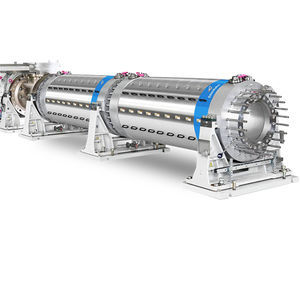

Saves energy and reduces costs

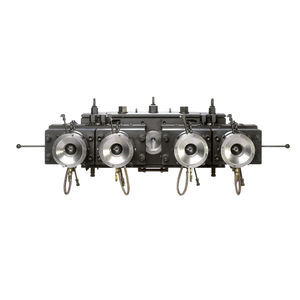

IPC works with ambient air, which is sucked through the pipe to be produced in the opposite direction to the extrusion direction by means of a side channel blower or a radial blower. To ensure high heat transfer, the air is drawn through the pipe at high velocity. This results in a turbulent air flow at the inner wall of the pipe.

*Increased productivity through output increase of up to 60%

*Reduction of the cooling distance by up to 40%

*Energy-efficient production due to low cooling water consumption

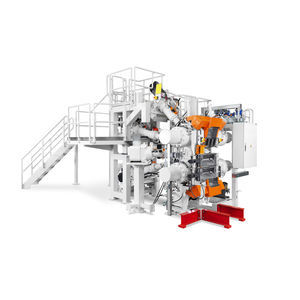

*Space-saving central melt feed system

Technical features

*Shortening the cooling section by up to 40% saves investment costs and space requirements or increased productivity through output increase up to 60%

*Low cooling water consumption and use of ambient air make for energy-efficient production

*Space-saving central melt feed with no risk of increased pressure build-up

*Continuously active IPC control maintains adequate air suction volume despite changing basic conditions to ensure consistently high product quality

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Injection press

- Screw extruder

- Horizontal injection press

- Hydraulic injection press

- Twin-screw screw extruder

- Thermoformer

- Plastic sheet extrusion line

- Automated thermoforming machine

- Pipe extrusion line

- Multilayer extrusion line

- PVC extrusion line

- Electric injection press

- Packaging thermoformer

- Vertical injection press

- Polypropylen extrusion line

- Single-screw screw extruder

- Polyethylene extrusion line

- Compounding screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.